Introduction

Welcome to the ultimate guide to A2L refrigerants, where we dive into what you need to know about A2L refrigerants in 2025 and beyond. As the world becomes increasingly conscious of the environmental repercussions of traditional refrigerants, the demand for A2L refrigerants is on the rise…

In this comprehensive guide, we will explore the ins and outs of A2L refrigerants, from their composition to their safe and efficient use. We’ll also discuss how A2L refrigerants differ from alternatives and the benefits they have in applications ranging from large-scale commercial refrigeration to residential air conditioning.

Regardless of your role in the HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) industry, be it as an OEM (Original Equipment Manufacturer), a panel builder, a seasoned technician, a business proprietor, or someone simply keen on staying well-informed about the latest developments in HVAC technology, this guide will arm you with the knowledge required to make informed decisions regarding A2L refrigerants.

What is a refrigerant?

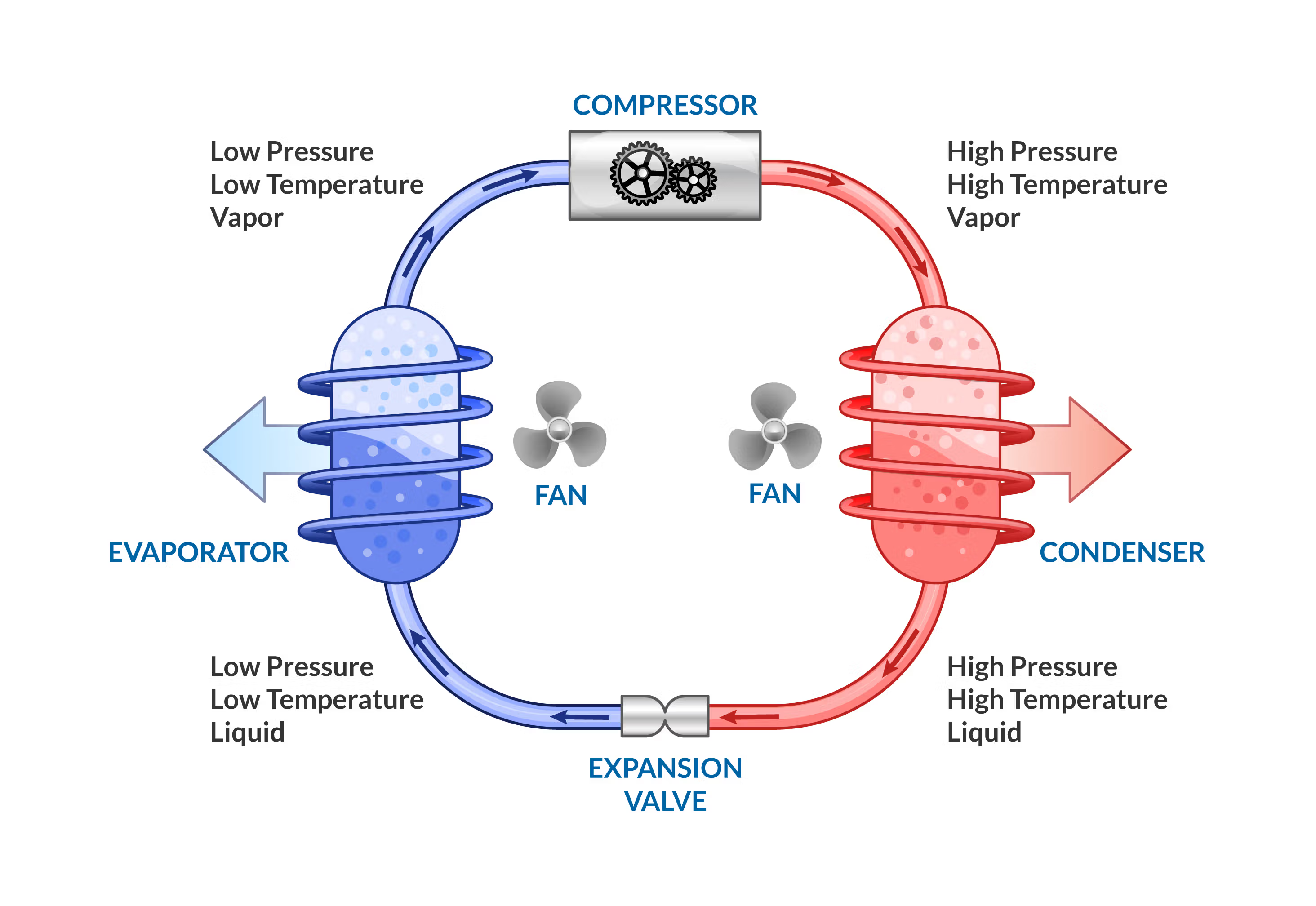

A refrigerant is a substance or compound used in the refrigeration cycle of air conditioning systems and heat pumps that facilitates the transfer of heat from one location to another. In most instances, refrigerants undergo a repeated phase transition between a liquid and a gaseous state. During this cycle, they absorb heat from the environment at a low temperature and pressure and release that heat at a higher temperature and pressure. This process is crucial in the cooling of systems.

Evolution of refrigerants

The history of refrigerants is characterized by a series of evolutionary leaps, each driven by technological advancements, growing environmental concerns, and evolving regulatory landscapes. The initial generation of refrigerants, dating back to the late 1800s, featured substances such as ammonia (NH3), sulfur dioxide (SO2), and methyl chloride (CH3CI). While these refrigerants proved to be effective, they raised substantial safety concerns. These concerns catalyzed the emergence of the second generation of refrigerants in the late 1920s - CFCs and HCFCs.

- Chlorofluorocarbons (CFCs): Compounds containing carbon, chlorine, and fluorine.

- Hydrochlorofluorocarbons (HCFCs): Compounds containing carbon, chlorine, and fluorine (like CFCs) as well as hydrogen.

Chlorofluorocarbons (CFCs) like R-12 and hydrochlorofluorocarbons (HCFCs) including R-22 gained prominence for their efficiency, non-flammability, and non-toxic properties. However, the 1980s unveiled the detrimental impact of CFCs and HCFCs on the ozone layer, leading to a phaseout of these refrigerants during the 1990s in favor of a third generation of refrigerants — hydrofluorocarbons (HFCs).

- Hydrofluorocarbons (HFCs): Compounds containing carbon, fluorine, and hydrogen.

With no chlorine atoms, Hydrofluorocarbons (HFCs) such as R-134a, R-410A, and R-152a, boasted zero ozone depletion potential, establishing themselves as an environmentally friendly alternative. However, they exhibited significant global warming potential (GWP) upon release into the atmosphere. With a growing global emphasis on combating climate change, the United States Environmental Protection Agency (EPA) implemented legislation in late 2021, mandating an 85% nationwide phasedown in HFCs by 2036. This phasedown includes restrictions on high GWP HFCs like R-134a (GWP = 1,400+) and R-410A (GWP = 2,000+) in all new chillers from January 1, 2025.

These stringent regulations have propelled significant interest in a fourth generation of refrigerants:

What are A2L refrigerants?

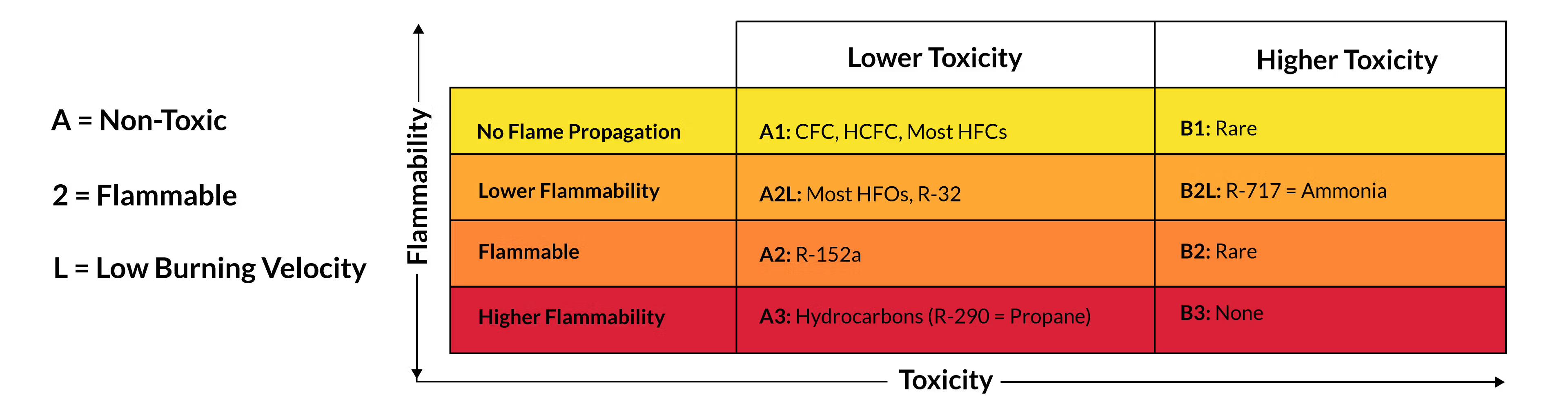

A2L refrigerants belong to a specific category of refrigerants that possess lower flammability and toxicity levels compared to other classifications. The ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) standard 34 safety classification and the ISO 817 standard provide a system for assigning designations to refrigerants:

- Hydrofluoroolefins (HFOs): Compounds that consist of carbon, fluorine, and hydrogen (the same atoms as HFCs). However, HFOs have a double bond between carbon atoms and lower GWP.

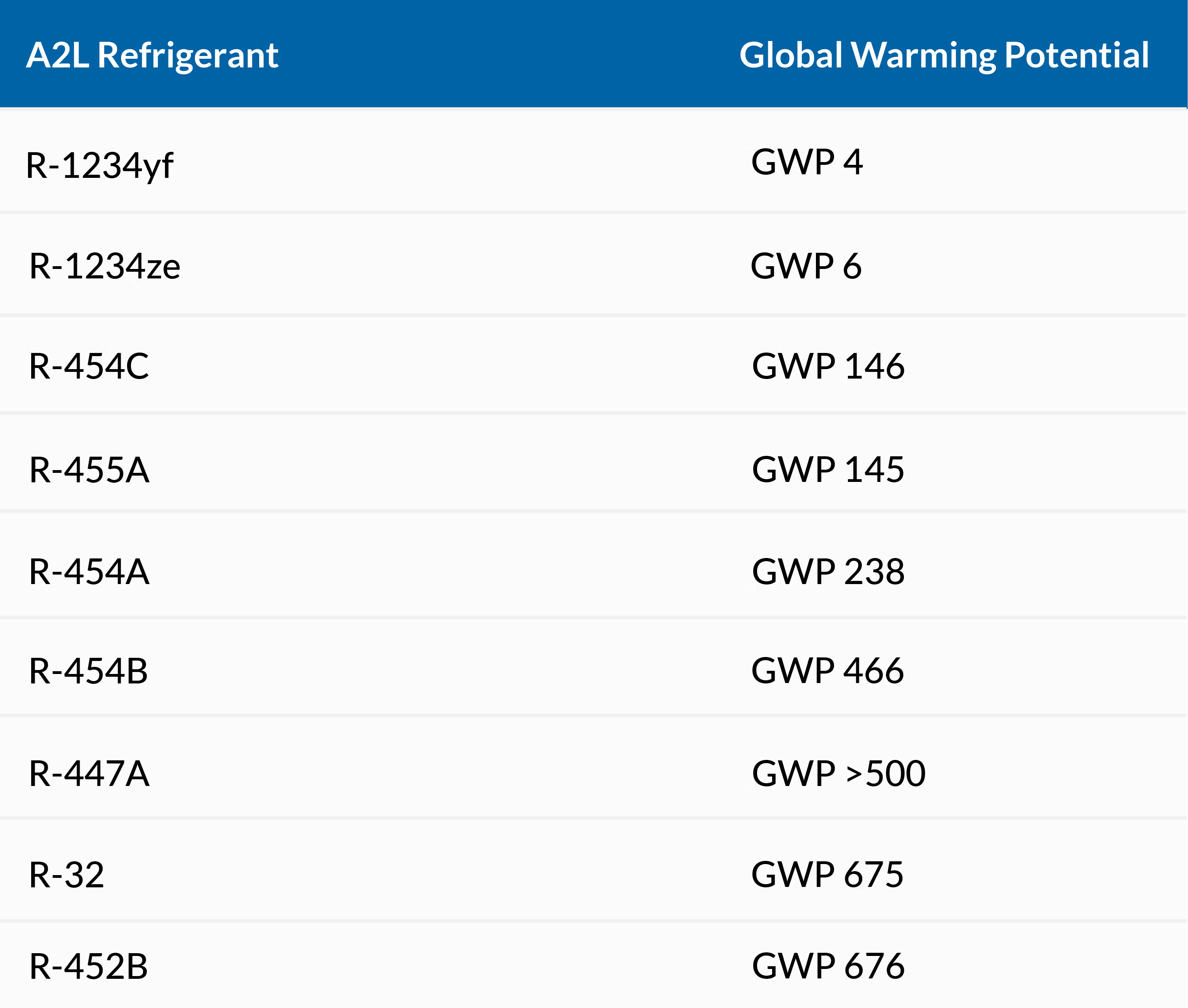

Common A2L refrigerant compositions include pure hydrofluoroolefins (HFOs) such as R-1234yf and R-1234ze, HFC/HFO blends such as R-452B and R-454B, and some pure HFCs such as R-32. These combinations result in a lower GWP while maintaining the cooling efficiency required for commercial and residential applications.

A2L refrigerants are used in a multitude of appliances, including air conditioners (ranging from window and room units to automotive systems), mini-splits, variable refrigerant flow systems, chillers, hot water heaters, and various other products. As of 2025, over 150 million A2L units have been installed globally, and over 85% of new vehicles sold in the United States incorporate an A2L refrigerant. As more businesses and industries make the transition toward lower GWP solutions, A2L refrigerants are poised to ascend further in popularity, primarily due to the manifold benefits they offer.

Benefits of A2L refrigerants

Environmental Impact

The foremost benefit of A2L refrigerants is the drastic reduction in GWP. For example, R-1234yf can offer over 99% less GWP than R-410A. Also, A2L refrigerants are also non-ozone depleting substances, helping achieve greenhouse gas reduction targets by addressing one of the major sources of emissions in HVAC systems.

Energy Efficiency

Many A2L refrigerants exhibit excellent thermodynamic properties, enabling efficient heat transfer and maintaining optimal cooling performance. Also, minimal energy waste compared to alternatives translates to reduced operating costs when utilized alongside the correct components.

Innovation

The development and adoption of A2L refrigerants has driven innovation in the realm of HVAC technology. New systems and components tailored for A2L can deliver improved system design, performance, safety, and more.

Regulatory Compliance

The use of A2L refrigerants aligns with agreements and regulations aimed at phasing down high-GWP refrigerants. These include the global Montreal Protocol and the Kigali Amendment and the regional US American Innovation and Manufacturing (AIM) Act.

Drawbacks of A2L refrigerants

Compatibility

While A2L refrigerants are relatively straightforward to use and don’t add excessive system complexity, they cannot be used in air conditioners, heat pumps, or other units designed for most older refrigerants such as R410-A. Transitioning to A2L refrigerants necessitates new equipment investments.

Flammability

Classed as mildly flammable, A2L refrigerants are unquestionably safe when managed correctly with due adherence to safety measures and system components. However, this requires extensive and specialized safety training for all personnel and testing of all components to verify reduced fire risks.

Upfront Costs

The upfront costs associated with procuring new equipment and implementing training programs to accommodate A2L refrigerants can be substantial. Nevertheless, the long-term savings potential is great, marked by enhanced efficiency (leading to lower operational costs), reduced refill volumes, and diminished per-refill expenses. Moreover, as production scales up, upfront costs are anticipated to recede over time.

Regulatory Compliance

While A2L refrigerants are in alignment with contemporary regulations, sustaining this compliance can be complex due to the amount of standards and the necessity for ongoing monitoring and compliance reporting.

Navigating the transition to A2L refrigerants

Armed with an understanding of the benefits and challenges associated with A2L refrigerants, it is evident that a transition plan demands careful planning and execution. The following steps can serve as a guiding framework:

- Assess the existing cooling systems: Evaluate the current refrigeration and air conditioning systems to determine what might be required to accommodate certain A2L refrigerants. Your equipment, application, and operating conditions will determine which A2L refrigerants you can utilize. (For reference, R-32 is common in residential air conditioners and R-454C and R-1234yf are common in mid-size systems).

- Consult with an HVAC professional: Seek guidance and expertise from an HVAC professional who specializes in A2L refrigerants. They can assess the feasibility of transitioning to A2L refrigerants and provide recommendations based on your specific requirements.

- Develop a transition plan: Craft a comprehensive plan that includes system modifications, equipment upgrades, and a robust safety framework. Take into account the potential costs, project timelines, and any regulatory obligations associated with the transition.

- Training and certification: Ensure that technicians and installers have the necessary training and certification to handle A2L refrigerants safely. This includes an in-depth understanding of the properties, safety considerations, and best practices for installing and servicing A2L refrigerant-based systems.

Conclusion

With the right planning and support, A2L refrigerants pave the path to a sustainable and efficient cooling system. Given that refrigeration technology and air conditioning account for approximately 20% of global electricity consumption, demand for energy-efficient solutions such as A2Ls will continue to grow as the world prioritizes environmental conservation.

Embrace and take the next step towards A2L refrigerants today to gain a competitive edge!

A note for OEMs and panel builders...

Given that A2L refrigerants are mildly flammable, UL standard 60335-2-40 outlines a spectrum of safety requirements, including protections against electric shock, fire hazard, and mechanical hazard. Components must successfully pass this UL testing before inclusion in A2L systems, even if they meet the standard without modification. As of January 1, 2025, North American OEMs will generally be required to use refrigerants with a GWP below 700 in new HVAC systems they manufacture or import.

Failure to comply with the UL 60335-2-40 standard would be extremely costly for HVAC manufacturers. To stay ahead and avoid losing business, OEMs and panel builders should contact their electrical control supplier(s) to confirm that they are, or have plans to be UL 60335-2-40 compliant.

How c3controls can help

At c3controls, we are prepared to fulfill requirements in the HVAC industry, as we have for the last 45+ years.

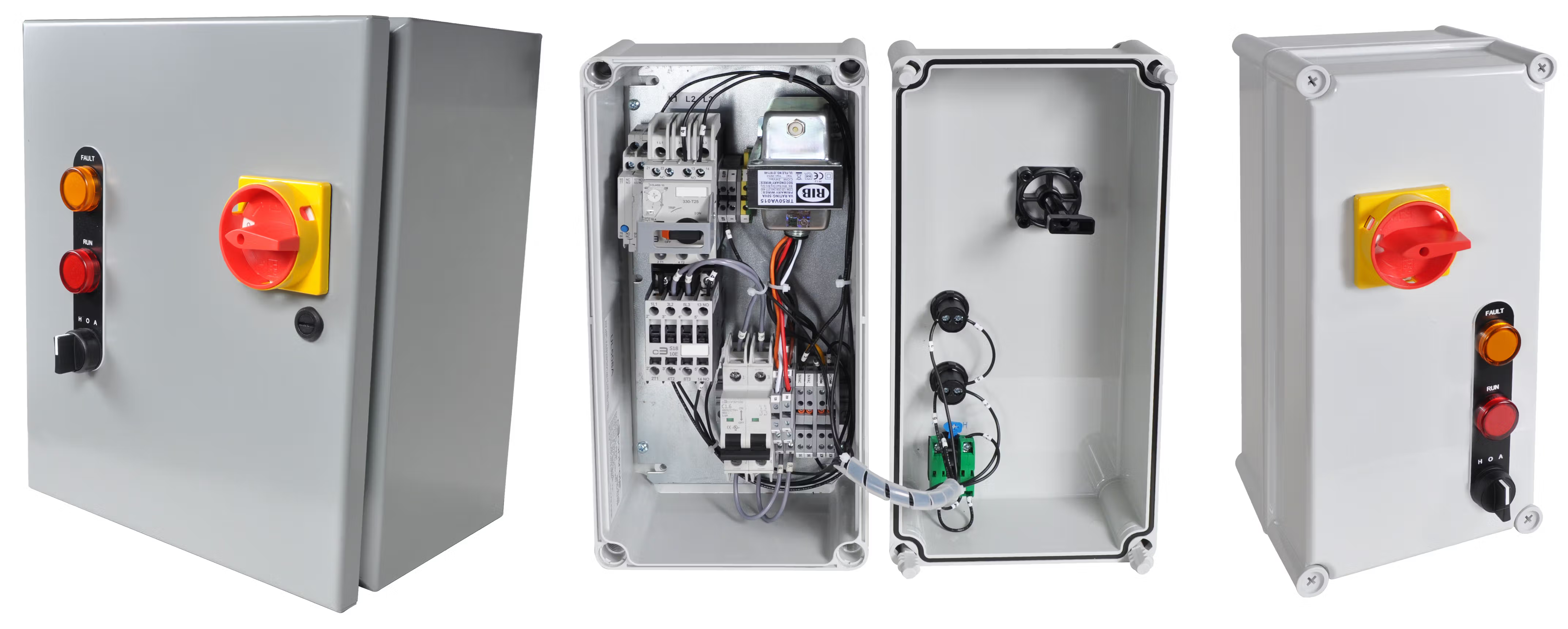

Explore component and finished solutions for all your air handling, chiller, heat pump, and ventilation system needs. That includes Enclosed UL508A Combination Motor Starters, and much more! With over 15 million product configurations and our own UL508A panel shop, c3controls has the resources you need to meet changing requirements and capitalize on your HVAC business opportunities.

----------------------------------------

Descargo de responsabilidad:

El contenido proporcionado en este documento técnico está destinado únicamente a fines de brindar información general y se proporciona en el entendimiento de que los autores y editores no se dedican a la prestación de servicios de ingeniería, consultoría u otros servicios profesionales. La práctica de la ingeniería está impulsada por circunstancias específicas y únicas para cada proyecto. En consecuencia, cualquier uso de esta información debe realizarse solo con previa consulta a un profesional calificado y con licencia que pueda tener en cuenta todos los factores relevantes y los resultados deseados. La información de este documento técnico se publicó con un cuidado y una atención razonables. Sin embargo, es posible que parte de la información contenida en estos documentos técnicos esté incompleta, sea incorrecta o no se aplique a circunstancias o condiciones particulares. No aceptamos responsabilidad por pérdidas directas o indirectas que resulten de usar, confiar o actuar sobre la información en este documento técnico.

ISO 9001:2015

Certificado

Más de 17 millones de productos

Configuraciones

Toda la vida

Garantía

Garantizado

Envíos en el mismo día

Precios ventajosos

Ahorre hasta un 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009