Introduction

Industrial pilot lights, also known as indicator lights or andon lights, play an important role in ensuring machines and electrical systems operate smoothly and safely. These small yet powerful lights are found on control panels, machines, and various equipment, where they provide a clear visual signal of the equipment’s status.

Throughout this article, the term pilot lights will be used frequently because they are essential components in industrial environments. This article will explain the different types of industrial pilot lights, their features, uses, and the many benefits of pilot lights.

What is a Pilot Light? Understanding Their Basics

A pilot light is a simple device that indicates when an electrical circuit is active or a machine is operating. In simple terms, it acts like a traffic signal, showing whether a device is on, off, in a warning state, or needs attention.

This visual feedback helps operators and technicians quickly understand the system condition without having to open panels or use specialized tools. For example, when a manufacturing machine starts running, an industrial pilot light on its control panel will glow green, letting the operator know it is operational.

These indicator lights help prevent accidents, speed up troubleshooting, and improve efficiency on the shop floor.

Types of Electrical Pilot Lights

There are several types of pilot lights used in industries, each with its unique advantages. Here are the most common types that you will encounter:

LED Pilot Lights

LED pilot lights are now the most popular type. They use light-emitting diodes, which are very energy-efficient and last a long time, often up to 100,000 hours. These lights consume less power and can withstand vibrations, making them perfect for tough industrial environments. LED lights are available in many colors, allowing operators to quickly recognize different machine states by color.

Incandescent Pilot Lights

Incandescent pilot lights use small filament bulbs, similar to the ones found in traditional light bulbs. Though they provide warm and bright illumination, they have a shorter lifespan compared to LEDs and consume more power. They are commonly used in legacy control panels or less demanding applications where cost is a factor.

Neon Pilot Lights

Neon pilot lights work well in high-voltage settings. These indicator lights use neon gas inside a small tube and glow when electricity passes through. Neon lights are energy-efficient and highly visible, but their brightness is lower than LEDs. Neon pilot lights are often found in older systems or heavy-duty applications where voltage levels are high.

Push-to-Test Pilot Lights

These indicator lights come with a test button that operators can press to verify the light is working correctly. This feature is especially important in safety-critical systems where regular checks are necessary to confirm the pilot light’s function.

Multi-Color Pilot Lights

Multi-color pilot lights provide the ability to change colors from a single device. This is useful in control panels where space is limited but different status indications are necessary. For example, one multi-color pilot light can glow green for normal operation and switch to red if there is a fault.

Multi-Voltage Pilot Lights

Multi-voltage pilot lights provide the ability to operate across a wide range of voltages from a single device. This is useful in control panels where flexibility is needed for different systems or applications. For example, one multi-voltage pilot light can work in both low-voltage and high-voltage environments without requiring separate models.

Watch the video for more: https://www.youtube.com/watch?v=W9TmyempOGk

Types of Lenses Available in Pilot Lights

- Flush/Flat Lens: A flush or flat lens keeps the pilot light even with the surface of the panel. This design gives a clean look and reduces the risk of the lens being hit or damaged. Flush lenses are often chosen for compact panels or installations where space is limited.

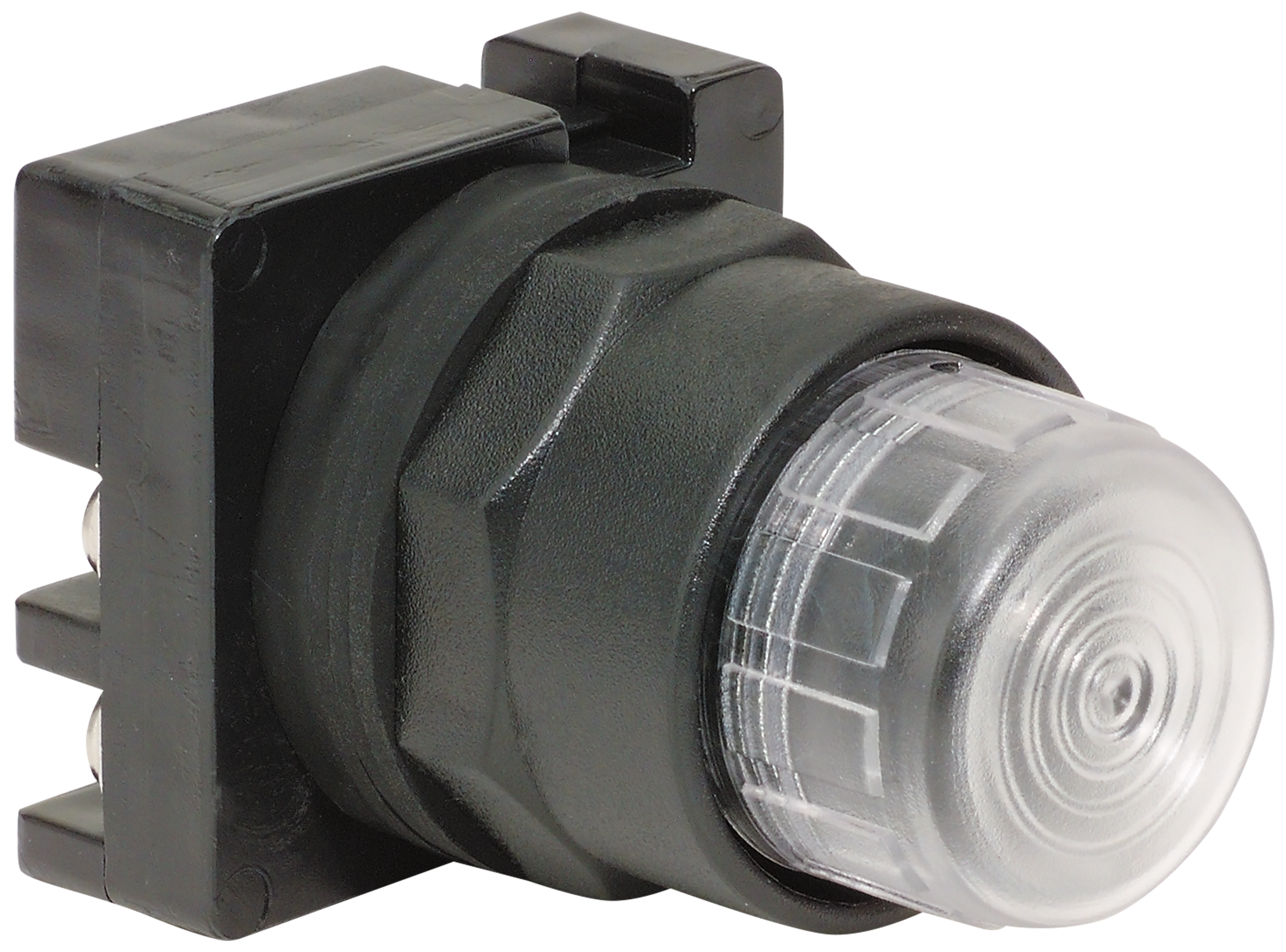

- Extended Lens: An extended lens allows the pilot light to stand out from the panel, making it easier to see from different angles or longer distances. This style is especially useful in bright industrial environments where visibility is critical.

- Guarded Lens: With a guarded lens, the pilot light is protected by a cover or ring around the lens. This prevents accidental bumps or impacts that could damage the light. Guarded styles are commonly used in heavy-duty industries where durability and safety are priorities.

- Conical Lens: A conical lens helps the pilot light spread its illumination over a wider viewing angle. This means operators can see the signal clearly even if they are not standing directly in front of the panel. Conical lenses are a practical choice in large facilities or control rooms where equipment is monitored from multiple directions.

Pilot lights come in two different versions, i.e., relampable & non-relampable versions.

Relampable pilot lights allow the light source (such as the bulb or LED module) to be replaced when it burns out or reaches the end of its lifespan. This makes them a cost-effective and flexible choice for applications where long-term maintenance is expected. Instead of replacing the entire unit, only the lamp needs to be changed, reducing downtime and saving on overall replacement costs. Relampable models are often preferred in environments where equipment is heavily used and quick maintenance is necessary.

Non-relampable pilot lights, on the other hand, are built as sealed, one-piece units. Once the lamp inside stops working, the entire pilot light assembly has to be replaced. While this may sound less convenient, non-relampable lights offer certain benefits. They are more compact, generally more resistant to dust and moisture, and reduce the risk of incorrect lamp replacement. These qualities make them suitable for environments where durability, reliability, and minimal maintenance are more important than long-term flexibility.

c3controls’ Industrial Pilot Lights

c3controls manufactures a wide range of industrial pilot lights designed to meet the needs of modern control panels and machinery. The product line includes LED, incandescent, and multi-voltage pilot lights available in various standard sizes such as 13mm, 16mm, 22mm, and 30mm Industrial & Hazardous varieties. These pilot lights are engineered for durability, safety, and ease of use.

Key features of c3controls pilot lights include:

- State-of-the-art LED light modules that can operate on any voltage from 20V to 277V AC or DC without losing brightness.

- Multi-voltage LED and full-voltage incandescent options to fit diverse industrial applications.

- Compact designs with depths as low as 45.6mm for space-saving installations.

- Certified or sustainable for Hazardous locations.

- Operators mount in standard round holes (e.g., 22.5mm for IEC models) that are directly interchangeable with competitor units, reducing installation time.

- Pilot lights have high environmental ratings (UL Types 4/4X, 12, 13, and IP66) for protection against water, dust, corrosion, and extreme environments.

- Polyester construction for outstanding corrosion resistance and electrical insulation.

- Long LED lamp life of up to 100,000 hours (about 11.4 years) for reduced maintenance.

- Available illuminated and non-illuminated push buttons and selector switches.

- Push-to-test and multi-color pilot lights for additional functionality and safety checks.

- Compliance with international standards, including UL 508, CSA, IEC, and CE marking for global acceptance.

- Modular contact blocks with captive wire clamps facilitate easy wiring and secure connections.

c3controls also offers unibody pilot light models that combine simplicity with durability, featuring rugged polycarbonate lenses for high visibility and impact resistance. These lights come in various colors with options for both LED and Lens.

Overall, c3controls pilot lights provide flexibility, quality, and reliability to meet a wide range of industrial signaling and indication needs while adhering to rigorous safety and performance standards. This broad product portfolio supports diverse manufacturing and automation environments, helping operators monitor and control processes efficiently.

Common Uses and Applications

Pilot lights serve as vital indicators across numerous industries and equipment types. Their ability to provide instant visual feedback makes them indispensable for operational safety and efficiency.

Manufacturing Industry

In manufacturing plants, pilot lights are installed on machine control panels to provide operators with immediate visual feedback about equipment status. They indicate whether a machine is powered on, running, in standby mode, or has encountered a fault. For example, on assembly lines, pilot lights signal the start or stop of conveyor belts or robotic arms. In machining centers, they show spindle operation or alarm conditions. This helps operators quickly assess the health of several machines at a glance without manual inspection, speeding up response and maintenance.

Automotive Industry

Pilot lights serve critical functions on automotive dashboards and control panels during vehicle production and diagnostics. On dashboards, these indicator lights alert drivers to engine problems, battery charging status, oil pressure issues, and other system warnings, promoting safe vehicle operation. In automotive manufacturing, pilot lights are used on testing stations and robot controllers to notify operators of line status, faults, or process completion, optimizing workflow and safety.

Electrical Control Panels

Pilot lights are extensively used in electrical distribution and control panels across industries. They indicate power availability, motor starter activity, breaker trips, and emergency stop activations. For example, in motor control centers, pilot lights light up when a motor starts or indicate overload conditions to prevent damage. In switchgear panels, they show circuit breaker status and fault alarms, enabling quick isolation of electrical faults and improved plant safety.

HVAC Systems

Heating, ventilation, and air conditioning systems rely on pilot lights to display operational modes and fault conditions. Pilot lights on HVAC control panels indicate whether heating or cooling systems are active, fan operation is on, or whether filters or sensors require maintenance. These visual cues help facility managers quickly identify HVAC system status for a comfortable and efficient building environment control.

Energy and Utilities

In power generation and utility sectors, pilot lights mark the status of transformers, generators, switchgear, and distribution equipment. They signal normal operation, power availability, fault conditions, or maintenance needs. For example, pilot lights on generator control panels indicate readiness, running status, or emergency stop activation, ensuring reliable power supply and operator safety in plants.

Food and Beverage Industry

Pilot lights are integral in automated food and beverage processing systems. They provide visual signals on packaging machines, filling lines, labeling machines, and conveyors. These lights show operational status, jams, low material levels, or safety warnings to operators, maintaining product quality, safety compliance, and efficient production.

Chemical Industry

Pilot lights in chemical plants are designed to withstand corrosive and harsh environments. They are installed on process control panels, pump stations, valve actuators, and hazardous zone equipment. These indicator lights provide status information on pumps running, reactor conditions, and fault alerts, ensuring safety by helping operators monitor critical process parameters reliably.

Commercial Buildings

In commercial settings, pilot lights are used on elevator control panels, fire alarm systems, security systems, and emergency lighting panels. They give building managers and maintenance staff immediate status updates on system readiness, fault warnings, or emergency activations. This quick visual feedback aids in maintaining occupant safety and operational continuity.

Common Colors of Pilot Lights and Their Meanings

Colors play a big role in the effectiveness of pilot lights. Different colors have universal meanings that help operators understand machine status at a glance:

- Red: Red commonly signals a fault, emergency stop, or danger. It warns operators to stop or take immediate action.

- Green: Green means normal operation or “ready.” When a pilot light glows green, it signals everything is working as expected.

- Yellow/Amber: Yellow usually indicates caution or standby. It tells operators to be alert or that a process is about to start or stop.

- Blue: Blue is often used to show special conditions or service modes. It can signal process-specific details like cold conditions in certain equipment.

- White: White generally means the system is powered on but may not be actively running a process.

Key Features to Consider When Selecting a Pilot Light

When choosing the right pilot light for your application, consider these important features to ensure safety, reliability, and optimal performance:

- Voltage Rating

Selecting a pilot light with the correct voltage rating is crucial for safe and efficient operation. Pilot lights are available for a broad range of voltages, from as low as 12V up to 600V AC or DC. Using the wrong voltage can cause premature failure or unsafe conditions. - Color Coding

Color selection should follow industry standards and the specific application to avoid operator confusion. Using consistent color schemes helps workers quickly understand machine or system status, improving response times and safety. - Size and Mounting

Pilot lights come in standard sizes such as 13mm, 16mm, 22mm, and 30mm to fit standard panel cutouts. Knowing the right size and mounting style ensures easy installation, proper fit, and compatibility with existing panels or equipment. - Environmental Protection

Consider the surrounding environment when choosing a pilot light. Models with IP65, IP66, or higher ratings offer protection against dust, water spray, and harsh conditions. This ensures durability and reliable operation in industrial environments like food processing, outdoor installations, and chemical plants. - Lamp Technology

LED pilot lights offer long life, low energy consumption, and better mechanical resistance, making them ideal for demanding applications. Incandescent pilot lights may be suitable for legacy systems where replacements match existing components. - Light Intensity and Visibility

The brightness of the pilot light should be sufficient for clear visibility under various lighting conditions, including bright daylight or dim control rooms. - Operating Temperature Range

Confirm the pilot light can operate reliably under expected temperatures, from cold storage to hot manufacturing areas. - Safety Standards and Certification

Choose pilot lights certified to meet relevant safety and quality standards such as UL, CSA, IEC, and CE to ensure compliance with industry regulations. - Ease of Maintenance

Pilot lights with replaceable lamps or modular designs make maintenance simpler and faster, reducing system downtime.

Benefits of Using Industrial Pilot Lights

Industrial pilot lights offer several key advantages that improve operational safety, efficiency, and cost savings in various applications:

- Enhanced Safety and Awareness

By providing clear visual signals, pilot lights reduce the risk of accidents and equipment damage. Operators can quickly see when a machine is running or if there is a fault, allowing for immediate corrective action. - Energy Efficiency and Cost Savings

LED pilot lights consume significantly less power than traditional incandescent lamps. Their longer lifespan reduces replacement costs and maintenance frequency, contributing to overall savings. - Improved Troubleshooting and Efficiency

Quick status indication from pilot lights helps maintenance personnel diagnose problems faster, reducing plant downtime and improving productivity. - Versatility and Customization

Pilot lights come in various colors, sizes, voltages, and functionalities such as push-to-test or multi-color capability, allowing them to be tailored for specific industrial needs. - Compliance and Reliability

Using pilot lights that meet international standards ensures safe operation and reduces liability risks in regulated environments. - Operational Continuity

Durable pilot lights designed for harsh industrial use minimize failures and interruptions, supporting continuous production operations. - User-Friendly Operation

Clear and intuitive indicator lights simplify machine monitoring for operators with different skill levels, reducing the likelihood of human error. - Environmental Resistance

Robust designs with protected housing and sealed lenses ensure pilot lights endure harsh conditions such as vibration, moisture, dust, and chemical exposure.

Market Growth and Usage Trends of Pilot Lights

The global market for explosion-proof pilot lights was valued at around USD 2.19 billion in 2024 and is expected to reach about USD 3.21 billion by 2031. This growth represents a compound annual growth rate (CAGR) of roughly 5.7% during the years 2025 to 2031. The steady increase in demand shows how important explosion-proof designs are for industries that operate in hazardous conditions, where safety and durability are top priorities.

In the United States, the Pilot Light Complete Units Market was valued at USD 0.4 billion in 2022, and it is projected to grow to about USD 0.6 billion by 2030. This rise demonstrates how U.S. industries continue to rely on pilot lights as part of their control systems, especially in manufacturing, automation, and other industrial sectors where quick and reliable visual signals are essential.

Along with this, the broader industrial lighting market, which includes pilot lights, is also experiencing significant growth. In 2024, the global industrial lighting market size was estimated at approximately USD 9.7 billion, and it is forecasted to reach about USD 14.3 billion by 2033, growing at a CAGR of around 4.15% from 2025 to 2033. The main driver behind this expansion is the increasing demand for lighting solutions that are both energy-efficient and durable. This includes industrial pilot lights, which are especially valued in hazardous and complex environments where they provide safety, reliability, and long-lasting performance.

In summary, industrial pilot lights or andon lights are vital for monitoring and controlling machinery. Using the right indicator lights helps businesses run safer, smarter, and more efficiently. This simple yet powerful technology continues to be a key part of industrial automation worldwide. For anyone setting up or maintaining control panels, understanding pilot lights is a must. Advances in LED technology and multi-color designs open new possibilities for clear and dynamic machine feedback in the years to come.

----------------------------------------

Disclaimer:

The content provided is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information was posted with reasonable care and attention. However, it is possible that some information is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this article.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009