Introduction

Material handling is a very broad category of equipment. Meaning, it can cover everything from moving small packages, to movement of rocks or aggregate in a mine. Control of the equipment varies by the product being moved. For example, a heavy product or a product that can tip over requires a gradual start of the conveyor. The product or machine may be such that it can be started at full speed without any consequences to the product.

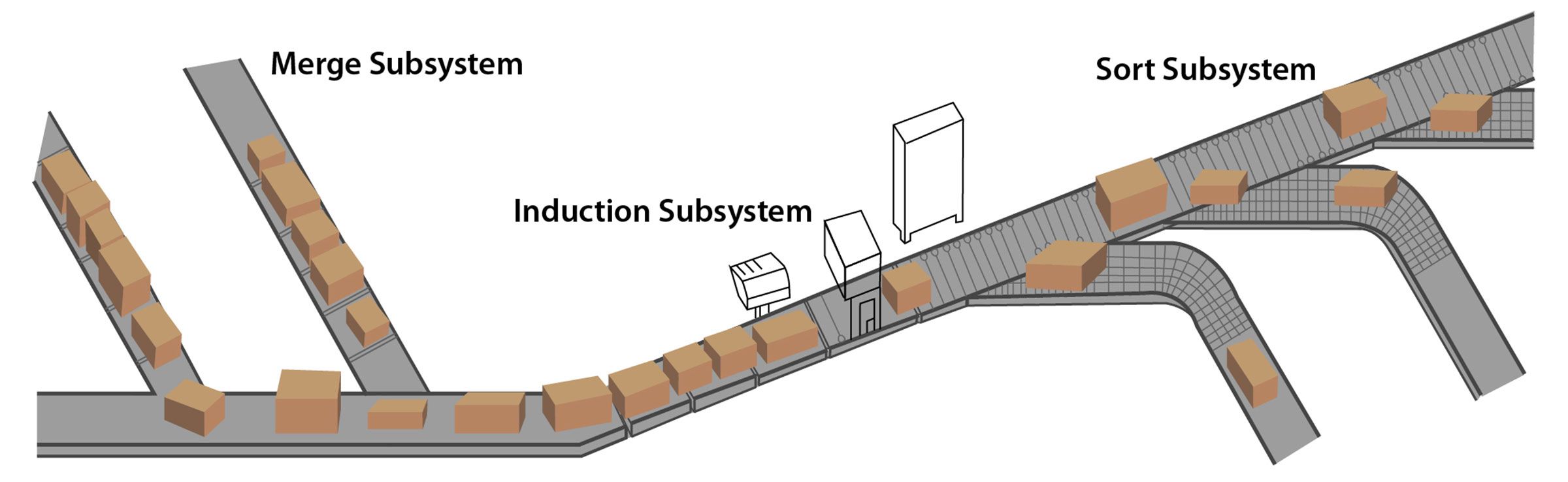

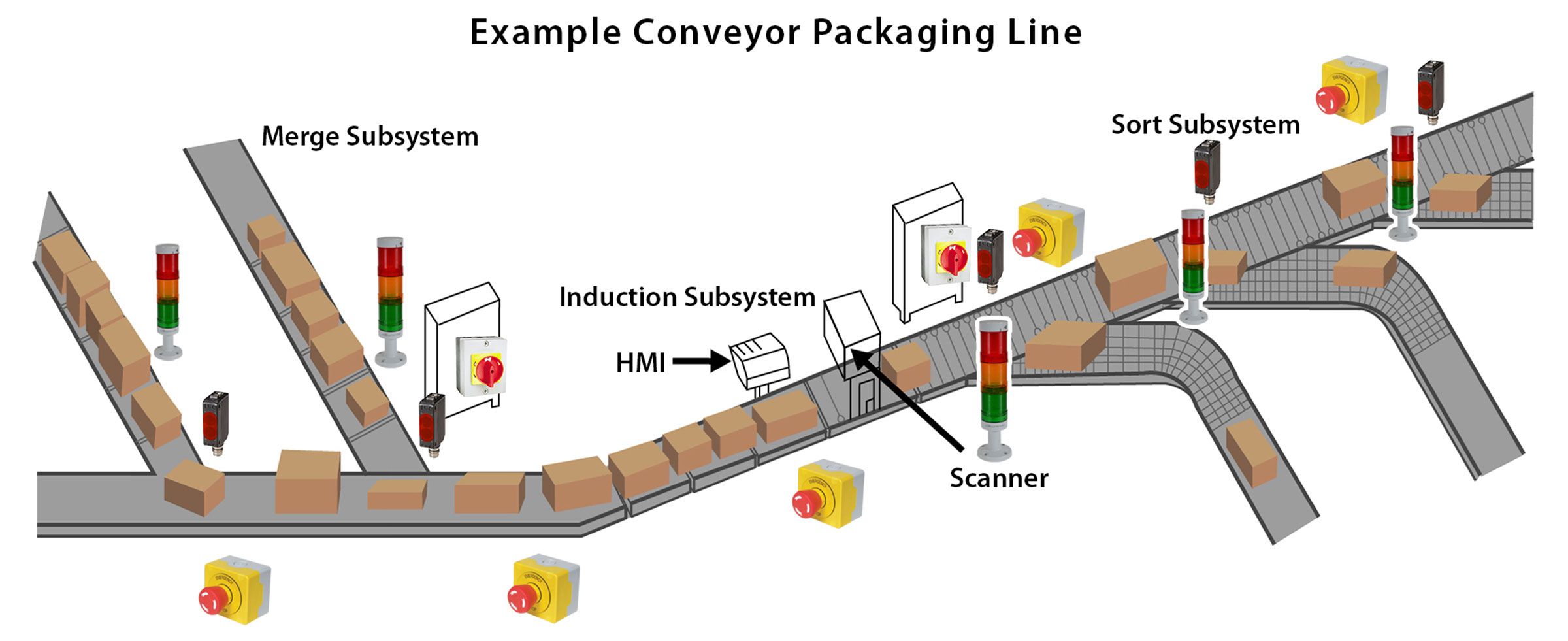

When designing and building subsystems independent of each other, the mechanical and electrical subsystems need to be well defined. The system in Figure 1 indicates there are solid or belt conveyors, control sections, and powered and non-powered roller conveyor areas. Independent of the material or product, the basic operation is the same. Each part of the overall system is connected electrically, with go-no-go signals from that section.

Take the system in Figure 1, the merge subsystem may have a stop or gate, so the packages stack up behind. The sort subsystem requires the packages to be spaced, so it can be diverted to the appropriate destination. To accomplish the correct package spacing, the induction subsystem handles the spacing of packages by starting and stopping the conveyor or packages.

Given the product and quantity one can determine what type of conveyor to use for a material handling system. Here are some items to consider when designing a system.

- Type of material or package

- Maximum size and weight

- Number and type of operator stations or points of operation

- Emergency stop stations (E-stop)

- Type of control, i.e., distributed or central

- Available power (electrical, pneumatic, and/or hydraulic)

Beyond these basics, the design of a material handling conveyor should also account for several broader factors that enhance system performance and long-term value.

Adaptability and Customization

Conveyors can be tailored for a wide variety of materials, from delicate parcels to heavy industrial components. Selecting components and layouts that protect product integrity is key, especially where damage during transport could impact quality or downstream processes.

Efficiency Through Automation

Automation has transformed material handling, with modern conveyors often equipped with sensors, programmable logic controllers (PLCs), and even artificial intelligence. These systems provide precise, reliable movement and tracking of goods, reducing manual intervention and minimizing human error. Automated conveyors can help reduce downtime, optimize workflow, and boost productivity throughout the facility.

Scalability and Integration

As operations evolve, so must your conveyor systems. Designing with scalability in mind allows for easy modifications or expansions, supporting business growth or shifting production needs. Additionally, conveyors should integrate smoothly with other material handling equipment—ensuring a cohesive, bottleneck-free operation.

Cost-Effectiveness Over Time

While the initial investment in a conveyor system can be significant, the benefits—greater efficiency, reduced product damage, streamlined labor, and improved inventory control—often lead to substantial cost savings in the long run.

Merge Subsystem

The merge subsystem may have several names such as: in-feed, off load, machine output, etc. Typically, this subsystem is designed with continuous feed and a storage or accumulator area. See Figures 2 and 3. This subsystem, like most material handling systems, may have rollers, belts, or table conveyors. All of these require a motor starter, circuit protection, pilot devices, PLC, sensors, and stack lights, just to name a few.

- Motor control may be: across the line starters, DC controllers, or VSD (variable speed drives).

- Operator interface may be pilot devices such as: selector switches, push buttons, pilot lights, stack lights, and E-stop stations.

- A PLC or other intelligent device with some form of sensor may also be used.

Induction Subsystem

The induction subsystem may have several names such as: spacing, selection, sort, etc. Typically, this subsystem is designed to accept material from the merge subsystem and space it out. This section may include inspection, sorting, or spacing. This subsystem may have timers or current sensor relays, in addition to that of the merge subsystem. The induction subsystem typically requires more intelligence than the other subsystems. The reason for this is that this subsystem controls both the spacing and to which sorting subsystem. This intelligence could be as simple as a timer or use a PLC to control spacing and sorting.

- Zone control typically controls the in-out device for proper spacing by sending a signal to the motor control.

Sort Subsystem

The sort subsystem sorts the materials to the appropriate destination. This is the point where the product may be packaged or headed off for shipment. The sort subsystem may be powered by electric and gravity and may include: diverters, elevators, lifts, slides, belt conveyors, accumulators, and/or powered/non-powered rollers. See Figure 5.

Gravity conveyors are a common component within the sort subsystem. These conveyors consist of a frame and rollers or wheels, and are pitched to allow gravity to move products smoothly along the line. Gravity conveyors are ideal for applications such as assembly lines, where items need to transition from one station to the next without powered assistance, or in shipping areas to efficiently move packages from the packing area to the truck. By leveraging both powered and gravity-fed elements, the sort subsystem ensures products are routed quickly and reliably to their final destination, minimizing bottlenecks and manual handling.

Each device requires: relays, operator interface, motor starter, circuit protection, pilot devices, diverters, position and product sensors, current sensor relays, stack lights, etc.

This sort subsystem has diverters that direct the product to the packaging or shipping area. Each diverter has to have input from sensors or controlled from the merge subsystem. A relay or communication device may be needed if the power requirements of the stack light, pilot device, diverter, or motor controller are greater than the output of the device. Additionally, there may be drops, shoots or conveyors that extend into the back of a large truck.

Types of Sortation Devices

To further illustrate, sortation systems can be designed with a range of different mechanisms, each suited for specific materials and throughput requirements:

- Shoe Sorters: These systems use sliding "shoes" that move diagonally across tubes or slats, gently nudging products to either side. Shoe sorters excel at handling a variety of product sizes and weights, making them a staple in retail distribution centers where items must be organized by store or region.

- Pop-up Wheel Sorters: Here, angled wheels rise up through the conveyor at designated points to divert lightweight, small to medium packages. Pop-up wheel sorters are commonly found in e-commerce fulfillment centers for sorting parcels to different destinations.

- Right Angle Transfers: These use a transfer head to push products off the main conveyor onto a perpendicular or parallel conveyor. Right angle transfers are ideal for maximizing space and enabling intricate networks of multiple conveyor lines.

- Arm/Pusher Sorters: This design diverts products onto chutes at 90-degree angles, often used in manufacturing facilities to separate items for specialized processing or packaging.

- Narrow Belt Sorters: Consisting of multiple narrow belts working in unison, these sorters can quickly and efficiently guide products left or right, and are often used for smaller items in retail, parcel handling, and e-commerce.

- Tilt Tray Sorters: These employ trays that tilt at the required station, sliding items smoothly onto the appropriate chute for sorting.

- Cross-Belt Sorters: Featuring individual belt segments mounted on a chain, each belt operates independently, enabling high-speed, accurate sorting of a wide variety of product shapes and sizes—especially popular in logistics, e-commerce, and retail distribution.

Each of these devices can be integrated into the sort subsystem, depending on the needs of the operation, the types of products handled, and the required speed and accuracy of the sorting process. No matter the method, the underlying principles remain the same: careful coordination of mechanical devices, sensors, and controls to direct products precisely where they need to go.

Conclusion

All of these subsystems add up to material handling applications widely used in every industry. This overview has been a brief summary of the concepts, machinery, and controls. Any application can be a complicated engineering challenge, and no two are exactly alike.

c3controls has been a key supplier to the material handling industry for decades. From motor control to pilot devices, circuit protection to disconnects, and everything in between. Below is a small example of where our products can be found.

FAQs

Q: What customization options are available for your conveyor and material handling systems?

Our conveyor and material handling systems can be fully customized to fit your specific operational needs. We offer options such as adjusting the size and layout to match your facility, selecting materials suitable for your environment (including stainless steel for food-grade or corrosive settings), and configuring belt types based on the products being transported. Systems can be tailored for speed control, integrated with automation like sensors and PLCs, and designed with features such as inclines, curves, and sortation zones. We also provide modular designs that allow for easy future expansion. By understanding your workflow and challenges, we ensure the final solution enhances efficiency, safety, and long-term reliability.

Q: Which advanced features or technologies help your conveyors operate more efficiently?

Our conveyors are designed with advanced features and technologies to ensure efficient, reliable operation across a range of industrial applications. Key technologies include variable speed drives for precise control of product flow, sensor-based automation for real-time monitoring and adjustments, and PLC integration for seamless system communication. Energy-efficient motors help reduce power consumption, while modular designs allow for easy maintenance and scalability.

Additionally, smart controls and diagnostics enable predictive maintenance, minimizing downtime and extending equipment life. Together, these features help streamline operations, reduce manual intervention, and enhance overall productivity.

Q: How are your conveyors designed to ensure safe and reliable operation on the production floor?

Our conveyors are engineered with safety and reliability as top priorities to ensure smooth operation on the production floor. Each system is built using high-quality materials and components that withstand the demands of continuous use. Safety features such as emergency stop buttons, protective guards, overload sensors, and lockout/tagout compatibility are integrated to protect both operators and equipment.

We also incorporate fail-safe controls and precision engineering to minimize downtime and reduce the risk of malfunctions. Regular quality checks and adherence to industry safety standards further ensure that every conveyor system operates dependably, even in high-demand environments.

Q: How do your conveyor systems support scalability as production needs grow or change?

Our conveyor systems are designed to grow with your business. They use a modular setup, which means parts can be added, removed, or reconfigured easily as your production needs change. Whether you’re increasing output, expanding to a new area, or introducing a new product, our systems can be adjusted without needing a complete replacement. This flexibility helps save time and money while keeping operations running smoothly.

Q: What industries or applications are your conveyor systems most commonly used in?

Our conveyors are used in a wide range of industries, including manufacturing, packaging, food and beverage, pharmaceuticals, and distribution centers. They’re great for moving all kinds of products—whether it’s bottles on a filling line, boxes in a warehouse, or delicate items in a cleanroom. We tailor each system to fit the specific needs of the job, making them reliable and efficient in just about any setting.

--------------------

Disclaimer:

The content provided in this document is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information in this document was posted with reasonable care and attention. However, it is possible that some information in this document is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this document.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009