Introduction

In the intricate world of electrical systems, miniature circuit breakers (MCBs) play an instrumental role in ensuring safety and system integrity. They guard against potential hazards like overloads and short circuits. With AC (Alternating Current) and DC (Direct Current) being the two primary electrical systems, understanding the distinction between AC MCBs and DC MCBs is crucial.

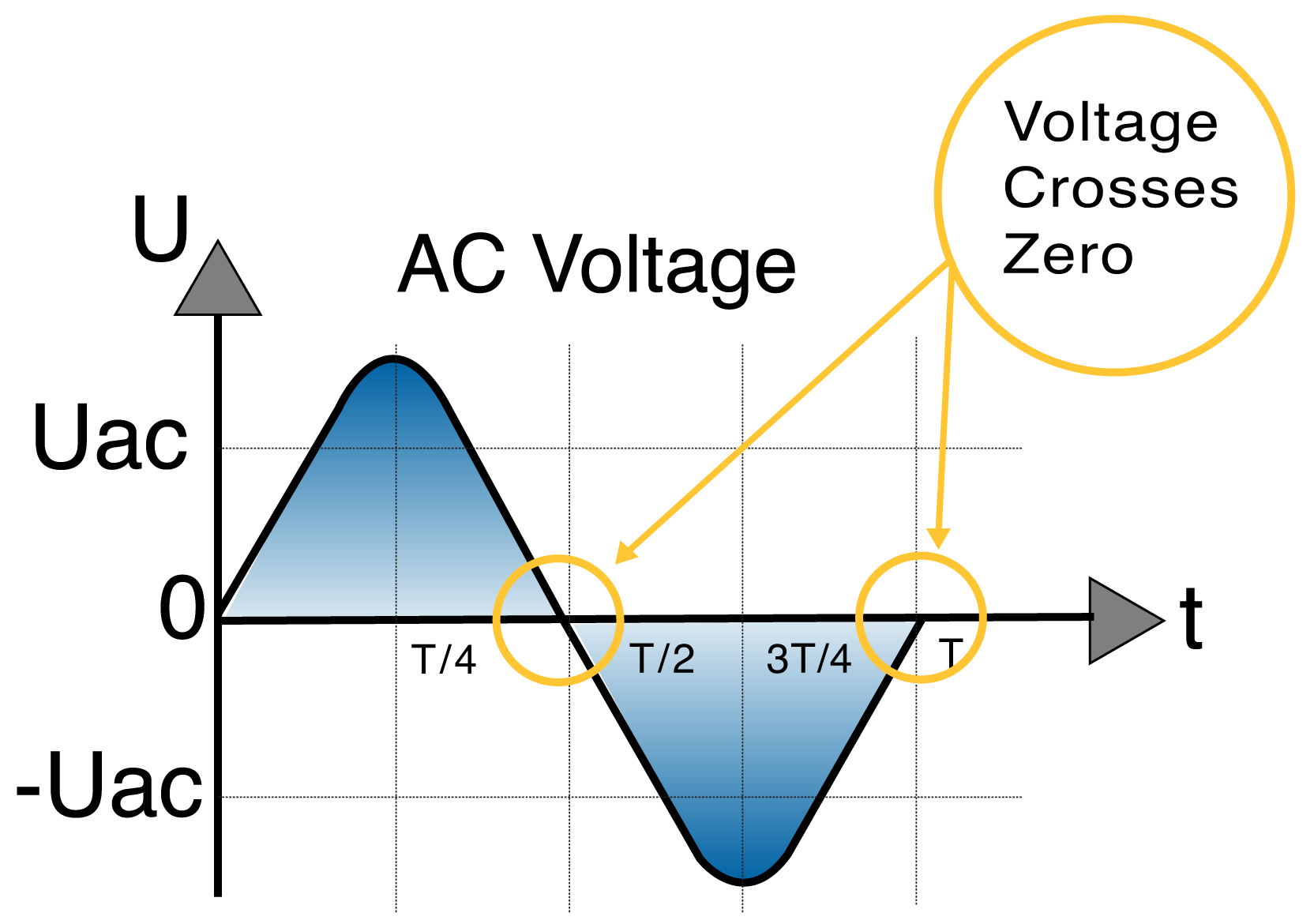

To start, let’s briefly review the differences between AC and DC.

Direction of Flow:

- DC (Direct Current): The electric charge flows in one constant direction. It can be either positive or negative, but the flow remains steady and doesn’t change direction.

- AC (Alternating Current): The electric charge changes direction periodically. In most common AC systems, the direction changes 50 or 60 times per second (known as the frequency, measured in Hertz - 50Hz or 60Hz depending on the country).

Source:

- DC: Typically comes from sources like batteries, solar panels, or DC generators.

- AC: Generated by power stations.

Applications:

- DC: Used in devices like cell phones, laptops, flashlights, and any device that uses batteries. Also essential for electronic systems and circuits.

- AC: Most commonly used for transmitting power over long distances, such as from power stations to homes and businesses. Most household appliances run on AC power.

Transmission:

- DC: Historically, it was difficult and inefficient to transmit DC over long distances. However, with the advent of high voltage DC (HVDC) technology, DC transmission has become feasible for long distances and is used in specialized scenarios such as connecting two different AC grids.

- AC: Easier and more efficient to transmit over long distances. Voltage can be easily stepped up or down using transformers, ideal for long-distance transmission (stepping up for transmission to reduce losses and stepping down for distribution and usage).

Voltage Level:

- DC: Stays constant over time unless changed by the user or due to battery depletion.

- AC: Voltage level alternates (often sinusoidally) between a positive peak and a negative peak.

The diagram below illustrates the fundamental differences between DC and AC.

Basics of Miniature Circuit Breakers (MCBs)

The modern miniature circuit breaker was invented by Hugo Stoltz in 1924. At their core, MCBs are automatically operated electrical switches, designed to protect electrical devices and human lives from electrical malfunctions. There are primarily two types: AC MCBs and DC MCBs. They function by interrupting electrical flow upon detecting short circuits and over current conditions, preventing damage.

AC Miniature Circuit Breakers

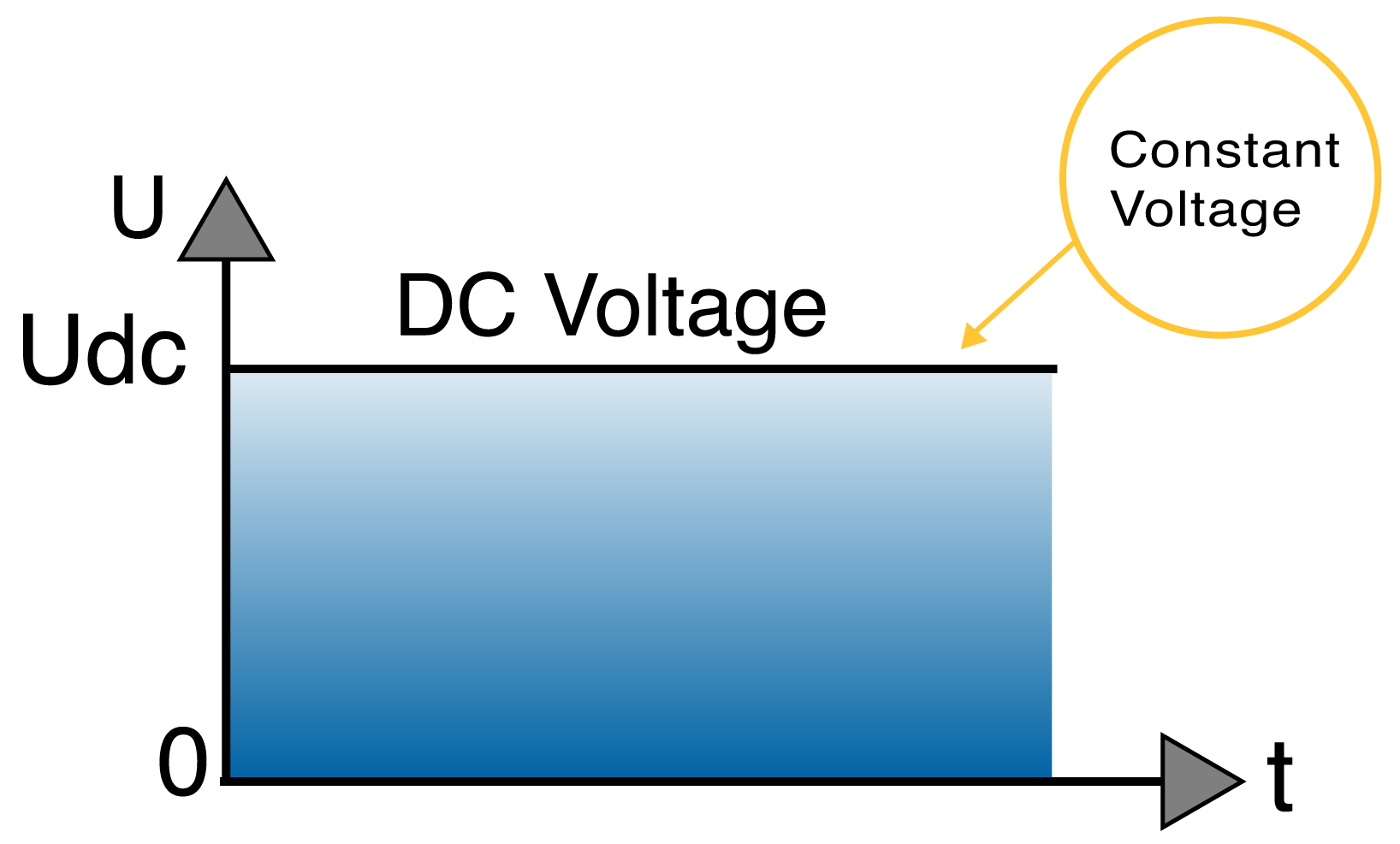

Working Principle:

AC MCBs are tailored for alternating current circuits. The key feature of AC is its zero-crossing nature, where the waveform crosses zero volts regularly. Each cycle of the AC waveform crosses zero twice. This characteristic aids in breaking the circuit, making the operation of AC MCBs relatively straightforward.

Benefits:

- Designed for AC waveforms: Their design leverages the frequent zero crossings in AC waveforms for efficient interruption.

- Availability and versatility: AC MCBs are omnipresent in residential and commercial setups due to their vast applications.

- Cost: The conventional choice, they are often more affordable than their DC counterparts.

Limitations:

- Unsuitability for DC: Using an AC MCB in a DC setup can be both inefficient and hazardous.

- Potential reduced lifespan: Misuse in DC circuits can lead to quicker wear and tear.

DC Miniature Circuit Breakers

Working Principle:

DC MCBs are designed for direct current circuits, where the current flows in a constant direction. Unlike AC, DC lacks natural zero-crossings, making breaking the circuit more demanding.

This is the key difference when designing a DC MCB. When breaking the circuit, the current “wants” to keep flowing in the same direction. (Current is not conscious, or hasn’t been proven to be, but it does seem to have a mind of its own.) Since there is no zero-cross point, breaking the circuit occurs at the full voltage. This creates a stronger arc, compared to AC.

To compensate for this difference, a DC MCB typically utilizes the following:

- Larger arc extinguishing chamber.

- Expanded distance between the moving contact and fixed contact.

- Addition of magnets to channel the arc into the arc extinguishing chamber.

- The magnets create polarity for the DC MCB and must be installed correctly to achieve the desired circuit protection and protect the MCB from damage. (Catching fire!)

Benefits:

- Tailored for DC systems: Tackle the constant nature of DC, ensuring safe disconnection.

- Indispensable for PV systems: They’re vital in photovoltaic systems, battery storage systems, and other renewable energy setups.

- Safety: Ensure that DC systems are protected from overcurrents and short circuits efficiently.

Limitations:

- Cost: Due to the intricacies in their design, DC MCBs often come with a heftier price tag.

- Size: They tend to be larger, attributed to significant arc suppression mechanisms.

- Availability: There are typically less DC MCBs on the market than AC MCBs.

Key Considerations When Choosing AC and DC MCBs

- Type of Current: The most obvious consideration is the type of current in the system. AC MCBs are designed for use with alternating current, while DC MCBs are designed for use with direct current. Using an AC MCB in a DC system (or vice versa) can be dangerous and lead to improper operation of the MCB.

- Voltage Rating: Ensure that the MCB is rated for the voltage level of the system. DC systems typically operate at higher voltages than AC systems, so it’s important to choose an MCB with an appropriate voltage rating.

- Current Rating: The MCB must also be rated for the maximum current that will flow through the circuit. This helps to ensure that the MCB will trip in the event of an overload, preventing damage to the electrical system.

- Tripping Characteristics: MCBs come with different tripping characteristics, known as Trip Curves, which define how quickly the MCB will trip in the event of an overload or short circuit. Choose an MCB with tripping characteristics that are suitable for the application.

- Breaking Capacity: The breaking capacity of an MCB is the maximum fault current that the MCB can safely interrupt. Ensure that the MCB has a sufficient breaking capacity for the electrical system in which it will be used.

- Compliance and Standards: Adherence to local electrical codes and standards isn’t just bureaucratic; it’s about safety and efficiency.

Does anyone make a MCB for both AC and DC?

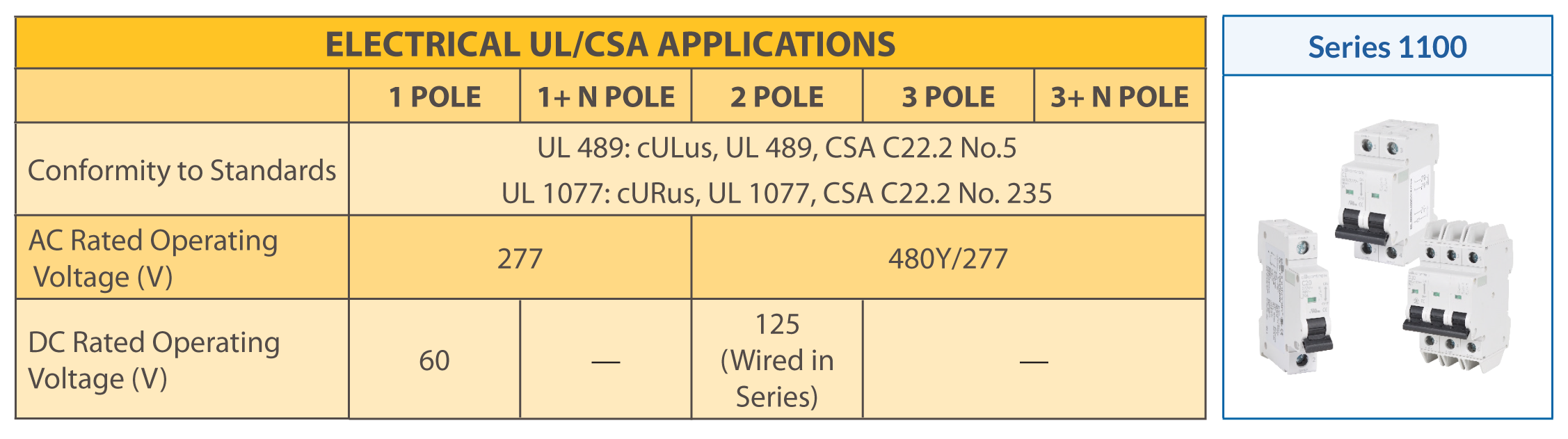

Yes. c3controls Series 1100 UL 489 Branch Circuit Breakers and UL 1077 Supplementary Protectors can handle both AC circuits and DC circuits. However, the operating voltages differ greatly. As shown below, a MCB designed for 277VAC can be used for 60VDC. To achieve a 125VDC Rated Operating Voltage (typical for DC applications), two are wired in series.

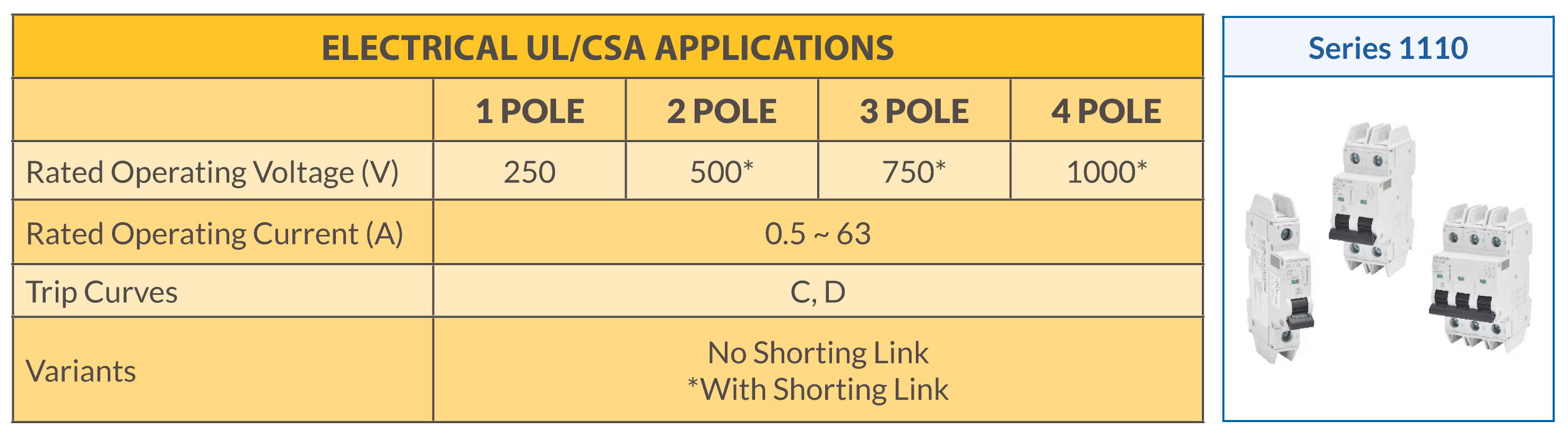

To meet the specific demands for higher voltage DC applications, c3controls has designed a line of circuit breakers specifically for DC circuits and UL 489B rated for photovoltaic applications. The Series 1110 DC MCBs have an operating voltage of 250VDC, per pole, with up to four poles.

Conclusion

Grasping the differences between AC MCBs and DC MCBs is paramount in ensuring the longevity and safety of electrical systems. The nuances between the two extend beyond mere terminology; they encompass design, application, and functionality. When in doubt, always reach out to electrical professionals—it’s always better to be safe than sorry.

----------------------------------------

Disclaimer:

The content provided is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information was posted with reasonable care and attention. However, it is possible that some information is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this article.

ISO 9001:2015

ISO 9001:2015 Certified

17+ Million Product

17+ Million Product Configurations

Lifetime

Lifetime Warranty

Guaranteed

Guaranteed Same-Day Shipping

Advantage Pricing

Advantage Pricing Save up to 40%

c3controls Headquarters, USA

664 State Street

Beaver, PA 15009

724-775-7926