Introduction

Electrical enclosures are critical components of various installations, protecting electrical and electronic equipment from environmental hazards. Two prominent standards evaluate these enclosures: NEMA Ratings and IP Ratings. While NEMA Ratings are primarily used in the United States, IP Ratings are a European standard. This guide provides a detailed understanding of NEMA Ratings, their types, and how they compare to IP Ratings.

What Are NEMA Ratings?

NEMA stands for the National Electrical Manufacturers Association, an organization responsible for developing technical standards for electrical and medical imaging equipment. Among its many responsibilities, NEMA is widely recognized for its rating system, which classifies enclosures based on their ability to protect equipment from environmental hazards such as dust, water, and corrosion. NEMA Ratings, outlined in the NEMA 250 standard, help identify enclosures suitable for specific environments. These ratings focus exclusively on enclosures, while IP Ratings (Ingress Protection) apply to a broader range of devices.

NEMA Ratings vs. IP Ratings

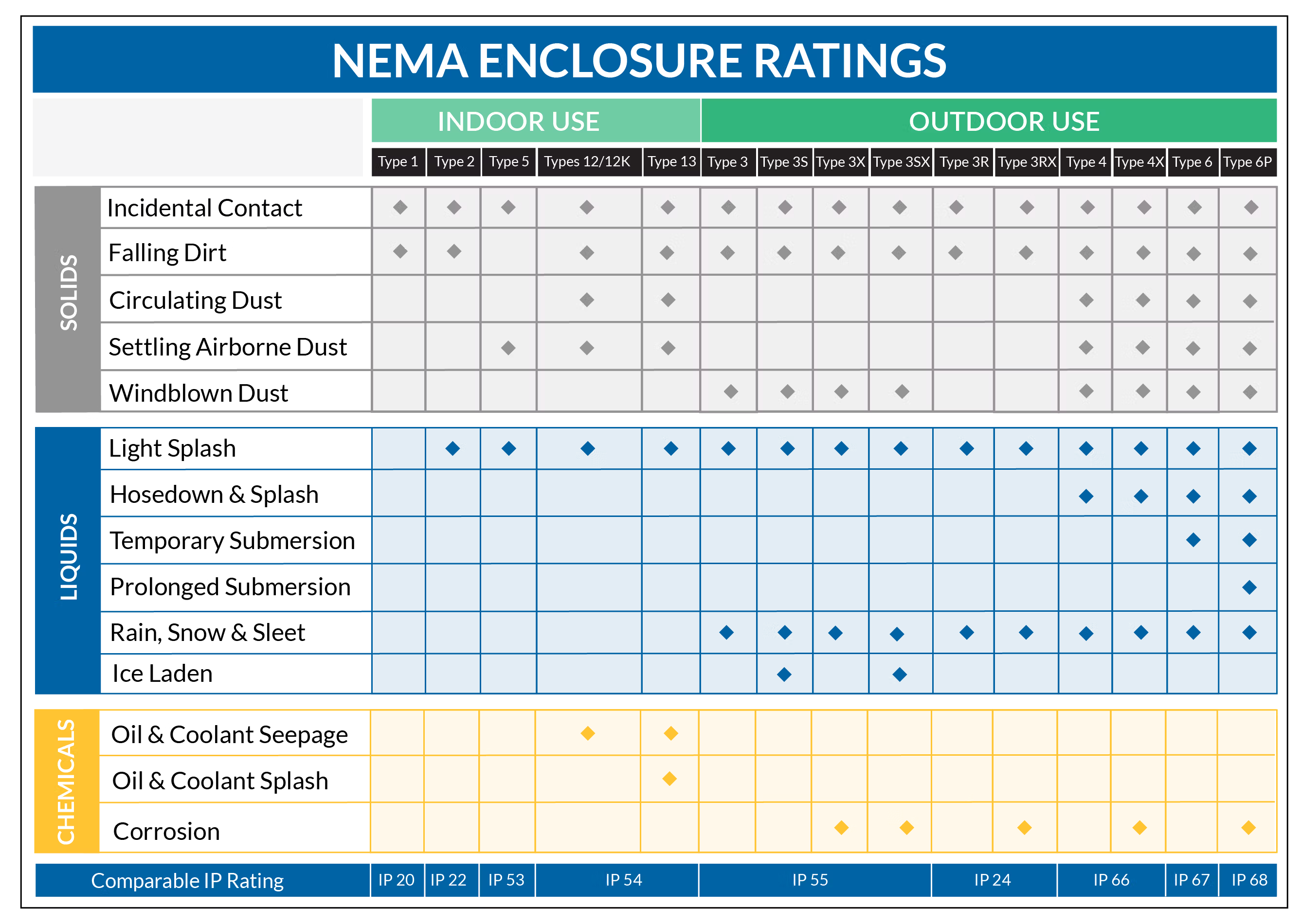

While both systems define protection levels, they use different testing methods and parameters:

- IP Ratings: Use a two-digit system (e.g., IP66), where the first digit indicates protection against solids (dust), and the second indicates protection against liquids (water).

- NEMA Ratings: Provide broader environmental considerations, such as protection against corrosion, ice formation, and hazardous atmospheres.

There is no direct conversion between NEMA and IP Ratings, but they offer comparable protection levels. For example:

- IP66 corresponds approximately to NEMA 4 or 4X, with NEMA 4X offering additional corrosion resistance.

Breakdown of NEMA Ratings

Non-Hazardous Locations

- Type 1: Indoor use. Protects against hazardous part access and falling dirt.

- Type 2: Indoor use. Offers Type 1 protection plus resistance to dripping or light splashing water.

- Type 3: Indoor/outdoor use. Protects against rain, sleet, snow, and dirt. Subcategories include:

- 3R/3RX: Rain-tight and corrosion-resistant.

- 3/3X: Added dust protection and corrosion resistance.

- 3S/3SX: Operable under ice formation, with corrosion resistance in 3SX.

- Type 4/4X: Indoor/outdoor use. Resistant to water ingress, including hose-directed water. Type 4X adds corrosion protection.

- Type 5: Indoor use. Protects against dust and light splashing.

- Type 6/6P: Indoor/outdoor use. Resistant to temporary (6) or prolonged (6P) submersion in water.

Hazardous Locations

- Type 7: Indoor use. Explosion-proof for hazardous areas.

- Type 8: Indoor/outdoor use. Explosion-proof with additional environmental protection.

- Type 9: Indoor use. Dust ignition-proof.

- Type 10: Meets Mine Safety and Health Administration (MSHA) standards.

Specialty Enclosures

- Type 11: Indoor use. Corrosion-resistant and protects equipment submerged in oil. Shields against corrosive fumes and gases.

- Type 12/12K: Indoor use. Rust-resistant and protects against dripping/splashing water. Type 12 lacks knockouts, while Type 12K includes them.

- Type 13: Indoor use. Similar to Type 12, but with added protection against oils and coolants.

Key Takeaways

- NEMA Ratings: Focus exclusively on enclosures, addressing broader environmental factors like corrosion and hazardous atmospheres.

- IP Ratings: Primarily address protection against dust and water ingress for a wider range of devices.

- Comparison: Higher numbers in NEMA Ratings do not always mean greater protection; the suitability depends on specific environmental hazards.

By understanding the nuances of NEMA Ratings, engineers and manufacturers can select the right enclosures for their applications, ensuring optimal performance and safety. Whether you’re dealing with dust, water, or hazardous conditions, knowing the appropriate rating can make all the difference in protecting your equipment.

----------------------------------------

Disclaimer:

The content provided is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information was posted with reasonable care and attention. However, it is possible that some information is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this article.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009