Introduction

In industrial automation, even a momentary power glitch can cause significant disruptions. Let’s say you’re managing a high-stakes production line when suddenly, a power supply issue brings everything to a grinding halt. The downtime costs you valuable time and money and risks damaging sensitive equipment and missing critical deadlines.

This scenario highlights a common problem in the industry—unreliable power systems. For businesses relying on industrial control systems, maintaining a stable power supply is crucial. This is where redundant power supplies can ensure your operations continue smoothly, even when unexpected power issues arise.

In this article, we’ll dive into how you can optimize your control system reliability using redundant power supplies. We’ll explore best practices to enhance system stability and prevent costly downtime.

Redundant Power Supplies in Industrial Control Systems

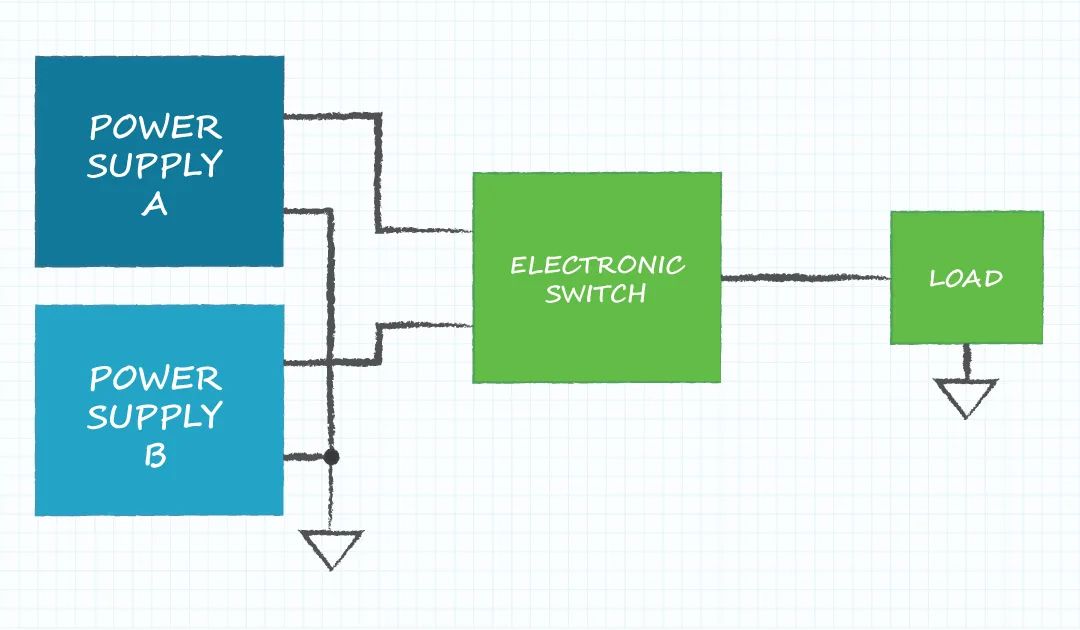

Redundant power supplies are essential components in modern industrial control systems. But what exactly are they? Simply put, a redundant power supply system includes multiple power sources that can take over if one fails.

Think of this as having a backup generator ready to kick in whenever there's a power outage. This setup ensures that your control systems keep running smoothly, no matter what.

Why is this important? In industrial environments, the cost of downtime can be enormous. Equipment failures, production delays, and even safety hazards can result from a sudden loss of power.

But how exactly do they prevent system failures? Let’s break it down.

Minimizing Downtime

You’re running a factory with automated machines humming along 24/7. Suddenly, the power goes out. Chaos, right?

But not if you have redundant power supplies. They kick in instantly, taking over from the failed primary source. The transition keeps your operations moving without a hiccup.

No downtime, no lost productivity, and no panic.

Preventing Data Loss

Now, think about all the data your control systems handle. A power blip can mean lost or corrupted data, throwing a wrench in your operations. With redundant power supplies, this worry fades away.

They ensure continuous power, so your data stays intact and processes run smoothly. For industries like pharmaceuticals or semiconductor manufacturing, where data integrity is crucial, this is a game-changer.

Enhancing System Stability

Power fluctuations can be the bane of sensitive equipment. They cause malfunctions and wear out your machinery faster.

Redundant power supplies step in here, too, providing a stable power flow that protects your equipment. This means fewer repairs and a longer lifespan for your machines.

Boosting Safety

Safety is paramount in any industrial setting. Imagine a chemical processing plant where cooling systems must stay operational to prevent overheating. A power failure here isn’t just inconvenient-it’s dangerous.

Redundant power supplies ensure that essential safety systems keep running, protecting your work force and preventing accidents.

Proactive Maintenance

Redundant power supplies make maintenance a breeze. You can service one power unit while the backup keeps things running.

Take a water treatment plant, for instance. Pumps and monitoring systems need to operate non-stop to ensure clean water. A power outage could mean contamination or equipment damage.

But with redundant power supplies, the backup kicks in instantly, keeping everything running smoothly. The result? Safe water and no costly repairs.

Difference Between Regulated and Unregulated Power Supply

Many people get confused about this: what's the difference between regulated and unregulated power supplies?

A regulated power supply is designed to maintain a constant output voltage, even when the input voltage or the load changes. Think of it like a thermostat for your power—it continually adjusts itself to ensure the devices downstream receive exactly the voltage they expect. This is essential when powering sensitive equipment or control circuits that can malfunction if the voltage fluctuates.

In contrast, an unregulated power supply has a much simpler design. The output voltage can vary depending on how much current your system draws or slight changes in the input. You might picture this as turning on more lights in your house and noticing a faint dimming—unregulated supplies don’t compensate for those changes.

When reliability and precision matter—like in most industrial applications—a regulated power supply is the clear choice. Unregulated supplies, while cheaper, are usually reserved for applications where voltage swings won’t cause issues.

Isolated vs Non-Isolated Power Supplies: What’s the Difference?

When choosing power supplies for your control system, you'll often come across two common types: isolated and non-isolated. The difference between them boils down to how they manage electrical separation between their input and output.

An isolated power supply—like those made by brands such as Siemens or Phoenix Contact—features a physical barrier, usually a transformer, that separates the input from the output. This isolation helps protect your sensitive control circuitry from voltage spikes, ground loops, or electrical noise coming from the main power source. Picture it as installing a buffer zone between your operations and the wild, unpredictable outside world—a bit like adding surge protection to your home’s electronics.

On the other hand, a non-isolated power supply directly connects its input and output without this separation. These are typically smaller, less expensive, and more compact, making them a fit for simple, low-voltage applications where space is at a premium and the risk of electrical interference is low.

Key differences to consider:

- Isolation: Isolated supplies provide electrical separation for increased safety and noise immunity.

- Cost and Size: Non-isolated units are generally more affordable and compact.

- Application: Use isolated supplies for critical or sensitive systems; use non-isolated for straightforward, low-risk circuits.

By understanding these distinctions, you can better match your power supply to the reliability needs of your control system.

Optimizing Power Supply Redundancy

Designing a redundant power system might seem daunting, but with the right approach, it can be straightforward and highly effective. Here are some best practices to guide you.

Assess Your Power Needs

First, understand your power requirements. Different systems have different needs, and knowing these specifics helps you choose the right type and number of power supplies.

For instance, a data center might need more robust redundancy compared to a small manufacturing unit.

Choose the Right Configuration

There are several configurations for redundant power systems. The most common ones are N+1, N+2, and 2N. In an N+1 setup, you have one extra power supply to back up the primary units.

N+2 means having two backups, and 2N involves doubling every power unit for maximum redundancy. Choose a configuration that matches your reliability needs and budget.

Quality Components Matter

Invest in high-quality power supplies and components. Reliable parts reduce the risk of failure and ensure longer system life.

Don’t cut corners here—quality components are a solid foundation for any redundant power system.

Regular Testing and Maintenance

Regular testing is crucial. Schedule routine checks to ensure all components are functioning correctly. This proactive approach helps identify and fix potential issues before they become serious problems.

During maintenance, you can service one power unit while the backup keeps the system running smoothly.

Documentation and Training

Keep thorough documentation of your power system’s design and maintenance schedule. Train your team to understand the system’s layout and emergency procedures.

The Advantages of Custom Power Solutions

When it comes to complex industrial environments, one-size-fits-all just doesn’t cut it. Enter custom power solutions—designed specifically to match your unique operational needs.

Tailored Performance:

Custom power solutions are engineered for your exact voltage, current, and environmental requirements. Whether you need extra filtering, unique form factors, or specific protections, these solutions fit like a glove—no wasted capacity or over-engineering.

Seamless Integration:

With a custom setup, you don’t have to worry about jury-rigging off-the-shelf units into your racks or enclosures. Every component is built to interface perfectly with your existing systems, simplifying installation and reducing the risk of compatibility headaches.

Enhanced Efficiency and Reliability:

Purpose-built designs often mean fewer points of failure and better thermal management. When your system only gets what it truly needs—no more, no less—you enjoy improved energy efficiency and greater reliability over time.

Scalability and Future-Proofing:

If you’re anticipating growth, custom power systems can be designed with modularity and easy expansion in mind. This means your investment remains useful as your needs evolve, saving you both time and money down the road.

Optimized Footprint:

Space is always at a premium. Custom power solutions can be designed to maximize every inch, keeping your control panels tidy and your facility organized.

Ultimately, going custom lets you engineer out inefficiencies and engineer in peace of mind—keeping your operations powered precisely how you need, when you need it.

Maintaining Industrial Control Systems' Power Condition Stability

Maintaining power condition stability is key to the longevity and reliability of your control systems. Here’s how to keep things steady.

Implement Surge Protection

Power surges can damage sensitive equipment. Installing surge protectors helps safeguard your systems against these sudden spikes, ensuring consistent power flow.

Use Uninterruptible Power Supplies (UPS)

UPS systems provide a buffer during power outages, giving your redundant power supplies time to kick in. It prevents abrupt shutdowns and protects your data and equipment.

Monitor Power Quality

Regularly monitor the quality of your power supply. Use tools to track voltage, frequency, and other parameters. Any deviations can indicate underlying issues that need addressing.

Environmental Controls

Maintain a stable environment for your power supplies. Excessive heat, humidity, or dust can cause failures.

Ensure your power systems are housed in a controlled environment to maximize their reliability.

Load Balancing

Distribute the power load evenly across your redundant power supplies. It reduces the risk of failure and extends the lifespan of your equipment.

Firmware and Software Updates

Keep all firmware and software up to date. Manufacturers often release updates that improve performance and security. Staying current ensures your system runs efficiently and safely.

Enhancing System Reliability With Backup Power Solutions

Let’s talk about keeping your industrial control systems running smoothly, even when the unexpected happens. Advanced backup power solutions are the key.

Battery Energy Storage Systems (BESS)

Imagine having a power bank, but on a massive scale. That’s what Battery Energy Storage Systems (BESS) are like. They store energy and kick in during power outages. This is perfect for industries with fluctuating power needs.

For instance, telecom companies use BESS to ensure that communication lines stay open, even when the grid fails.

Industrial DC Backup Systems

These systems are a personal power reserve for your most critical equipment. Industrial DC backup systems use a mix of energy storage technologies, such as lithium-ion batteries and supercapacitors, to keep things running smoothly.

They provide power directly to vital components during grid disturbances, which is a game-changer for maintaining stability and efficiency.

Uninterruptible Power Supplies (UPS)

UPS systems are the superheroes of backup power. They provide immediate power during outages, giving you time to shut down systems properly and avoid data loss or equipment damage.

Advanced backup power solutions are essential for maintaining the reliability of your industrial control systems. Whether it’s through BESS, industrial DC backups, or UPS systems, these technologies provide robust protection against power disruptions.

Challenges in Power Redundancy Implementation

Implementing power redundancy in industrial control systems can be challenging. However, with the right approach, these obstacles can be effectively managed. Let’s look at some common challenges and how to overcome them.

High Initial Costs

One of the biggest hurdles is the high upfront cost of setting up redundant power systems. Investing in additional power supplies, batteries, and infrastructure can be expensive.

Complexity in Design and Integration

Designing and integrating a redundant power system into existing setups can be complex. It requires careful planning to ensure compatibility and efficiency.

Space Constraints

Industrial facilities often have limited space for additional equipment. Finding room for extra power supplies and batteries can be a logistical challenge.

Maintenance Requirements

Redundant power systems require regular maintenance to ensure reliability. This can add to operational burden and costs.

Technical Expertise

Implementing and maintaining these systems requires specialized knowledge and skills, which may not always be readily available.

Effective Solutions and Best Practices

To manage costs, start with a thorough cost-benefit analysis. Prioritize critical systems for redundancy to ensure you’re investing where it matters most.

Look for scalable solutions that allow you to expand your system as needed, spreading out the costs over time.

Simplify Design and Integration

Work with experienced engineers to design your system. They can help simplify the process by recommending compatible components and configurations.

Modular designs can make integration easier and more flexible.

Optimize Space Utilization

Consider compact and modular power supplies that fit into tight spaces. Vertical racks or wall-mounted units can be used to maximize space efficiency.

Plan your layout carefully to make the best use of available space.

Regular Maintenance Plans

Develop a proactive maintenance schedule to keep your system in top condition, including:

- Regular testing

- Cleaning

- Component replacements as needed

Document all maintenance activities to track the system’s health over time.

Invest in Training

Ensure your team has the necessary skills to manage and maintain the redundant power systems. Provide training and resources to keep them up to date with the latest technologies and best practices, including:

- Workshops

- Certifications

- Ongoing education programs

Future Trends in Power Redundancy

Let’s talk about what’s new and exciting in the world of power redundancy. The landscape is evolving fast, and here are some of the trends shaping 2024.

Artificial Intelligence and Predictive Analytics

AI is making waves in power redundancy by boosting predictive maintenance and efficiency. Imagine AI algorithms that can predict potential failures before they happen.

For instance, AI can optimize energy usage in data centers, saving costs and enhancing efficiency.

Distributed Power Sources and Edge Computing

We’re seeing a shift towards distributed power sources and edge computing. This approach processes data closer to its origin, which reduces latency and enhances reliability.

Distributed power systems, including modular data centers and localized generation like rooftop solar and battery storage, add resilience and flexibility. It is perfect for maintaining operations during grid disturbances.

Solid Oxide Fuel Cells (SOFCs)

SOFCs are becoming a game-changer for clean, efficient, and reliable power. They convert fuel to electricity without burning it, resulting in fewer emissions.

SOFCs are highly efficient and can be integrated into microgrids, ensuring continuous operation even when the main grid is down. They are ideal for data centers and other critical infrastructure that need 24/7 power.

Integration of Renewable Energy and Energy Storage

Combining renewable energy sources like solar and wind with advanced energy storage solutions is a big trend.

Large-scale battery storage systems provide backup power and help stabilize the grid by balancing the intermittent nature of renewables. The result is a consistent and reliable power supply while promoting sustainability.

Enhanced Monitoring and IoT Integration

The Internet of Things (IoT) is supercharging monitoring capabilities. IoT devices provide real-time data on:

- Power usage

- System performance

- Environmental conditions

The data from IoT helps make informed decisions, optimize power distribution, and improve system reliability.

Decentralization and Modularity

Moving towards decentralized control systems reduces the reliance on single points of failure. Modular and scalable systems allow for incremental upgrades and localized control, enhancing resilience and adaptability.

The trend is especially beneficial for industries with diverse and geographically dispersed operations.

Sustainability and Efficiency

Sustainability and energy efficiency are becoming key priorities. Technologies like SOFCs and energy storage systems provide reliable backup power and help reduce the carbon footprint of industrial operations.

SOFC aligns with global efforts to combat climate change and promote renewable energy adoption.

Ensuring Reliability With Redundant Power Supplies

Reliable power is crucial. Redundant power supplies are the backbone of ensuring your control systems stay operational, no matter what. By leveraging AI, distributed power sources, and advanced energy storage, you can achieve unmatched reliability and efficiency.

Ready to enhance your system’s reliability? Explore the top-notch solutions from c3controls. As an industry leader in electrical controls, c3controls excels in delivering innovative, high-quality products designed to keep your operations running smoothly.

Discover more about how c3controls can support your power redundancy needs and ensure your systems never miss a beat. Shop with us today!

----------------------------------------

Disclaimer:

The content provided is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information was posted with reasonable care and attention. However, it is possible that some information is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this article.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009