Can I Use Standard Motor Control in Place of a Variable Frequency Drive?

The chip (Integrated Circuit) shortage, combined with energy and raw material shortages have created the perfect storm of forces that have resulted in a crisis for manufacturers looking to expand, upgrade, or improve their operations.

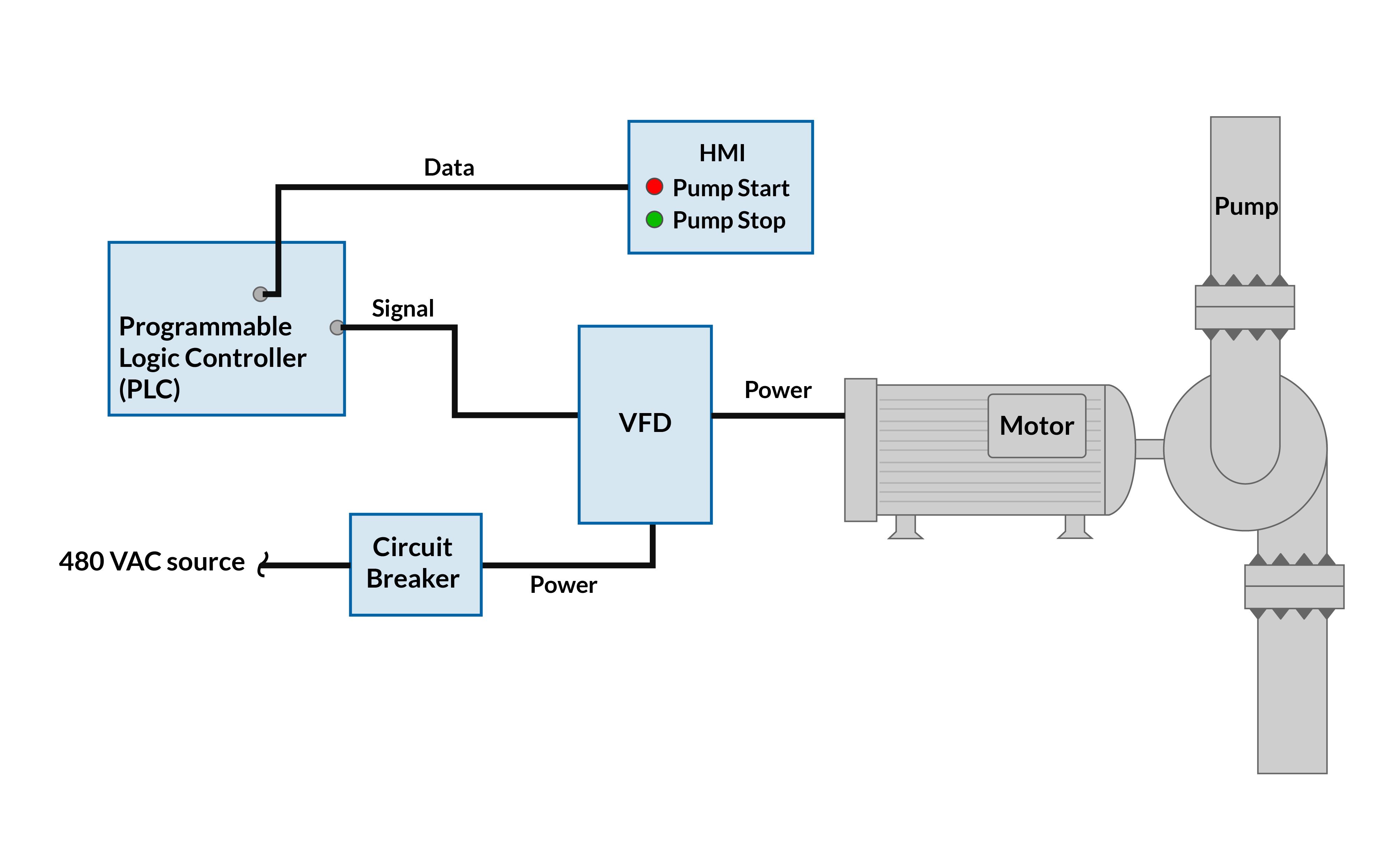

Programmable Logic Controllers (PLCs), Human Machine Interface (HMI), Drives, and other intelligent devices have become difficult to source. While geopolitical analysts have been talking about de-globalization and the reshoring of high-tech manufacturing, that process will be long and arduous. We should not expect things to get easier anytime soon.

Because of these factors, many companies have been finding themselves in a bind sourcing Variable Frequency Drives (VFDs) and Soft Starters and therefore are looking to more traditional control means. The question of “Can I use a standard electric motor starter in place of a VFD?” has crossed more than a few minds. The answer is, “Yes, in some cases.”

This short paper is not intended to be an exhaustive application guide of VFDs vs Electrical Motor Starters, but is rather to get you thinking about it.

What is a VFD?

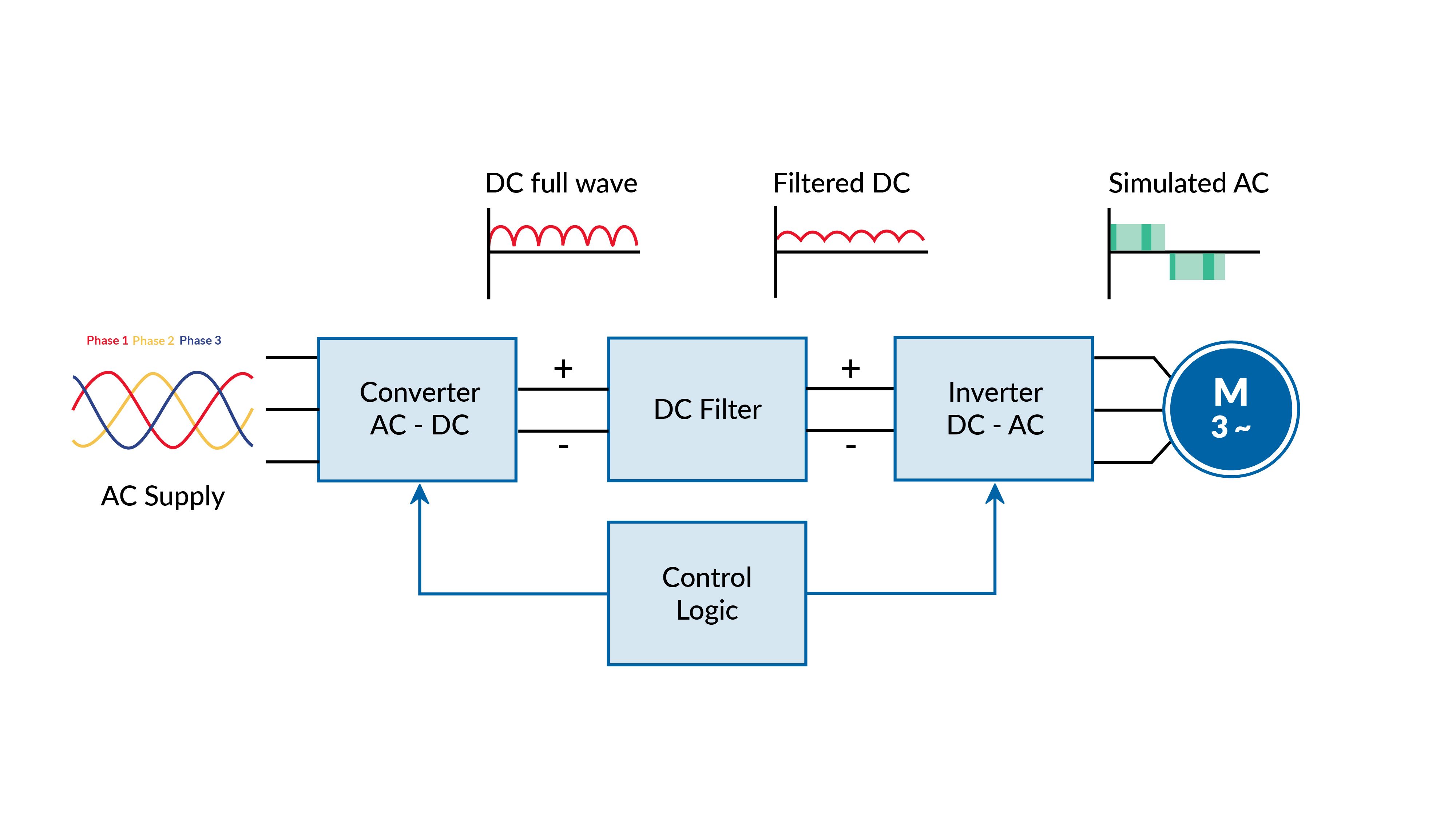

A Variable Frequency Drive (VFD) is a type of motor controller that drives an electric motor by varying the frequency and voltage supplied to the electric motor. Other names for a VFD are variable speed drive, adjustable speed drive, adjustable frequency drive, AC drive, microdrive, and inverter.

Frequency (or hertz) is directly related to the motor’s speed or revolutions per minute (RPMs). In other words, the faster the frequency, the greater the RPM. If an application does not require an electric motor to run at full speed, the VFD can be used to ramp down the frequency and voltage to meet the requirements of the electric motor’s load. As the applications motor speed requirements change, the VFD can simply turn up or down the motor speed to meet the requirement. - Source: vfds.com

VFD Circuit Diagram

VFD in a Pump Control Application

What is a Motor Starter?

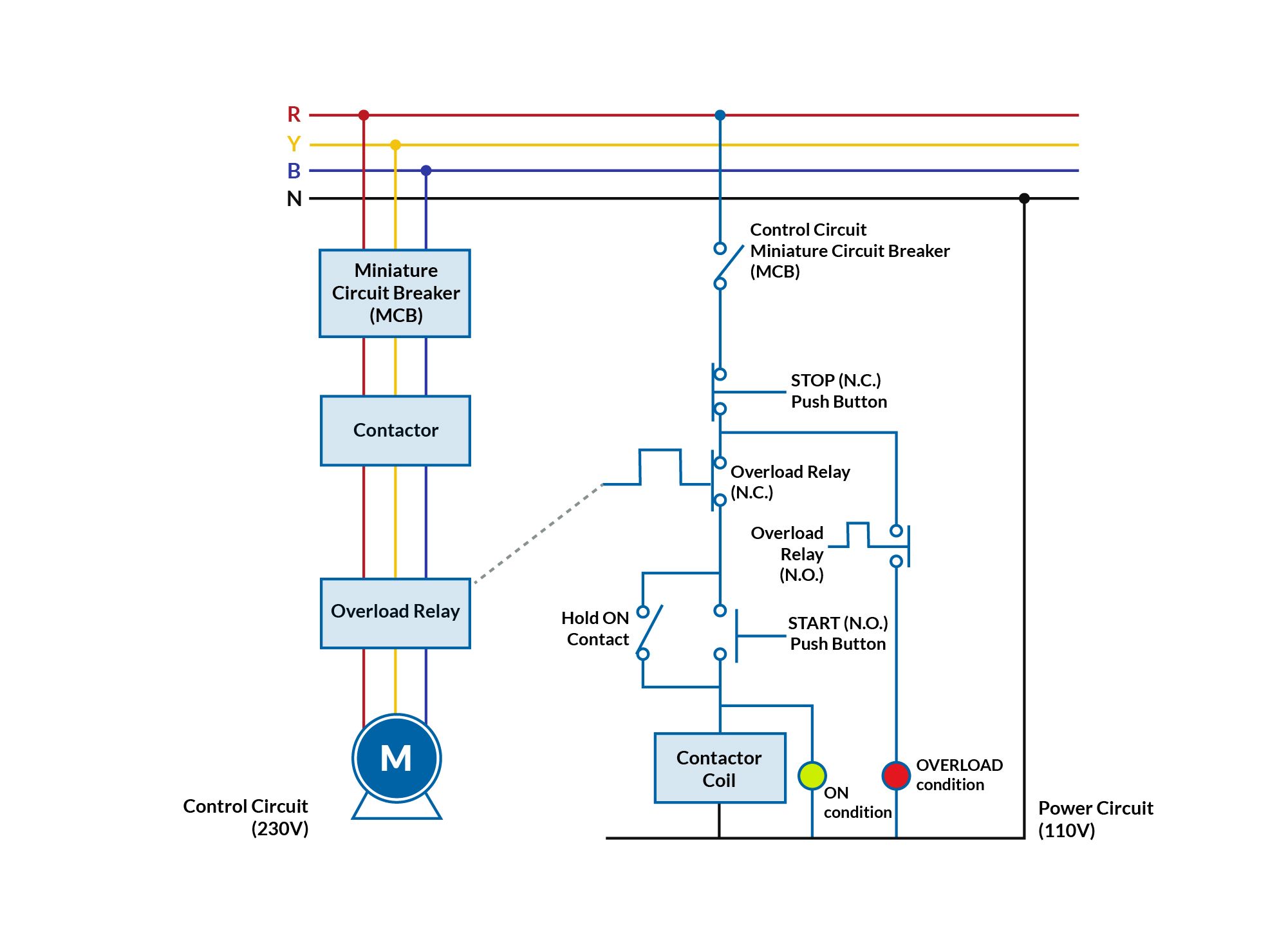

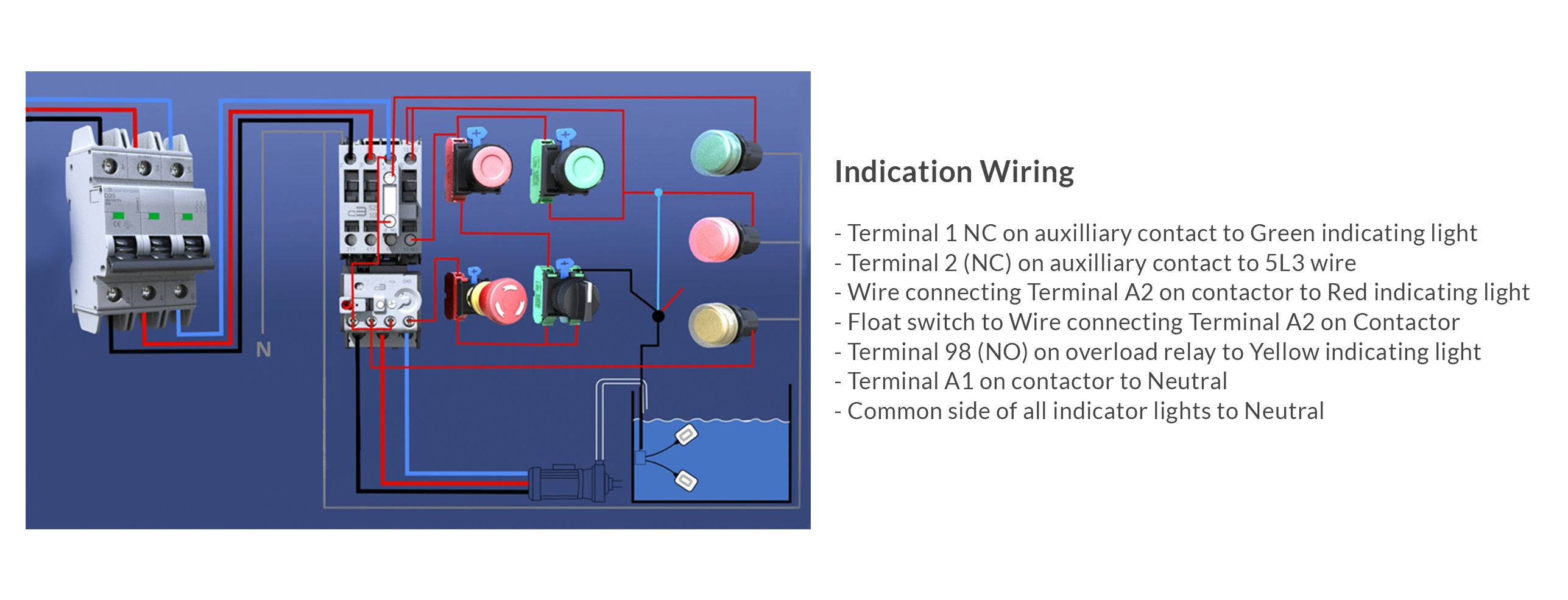

A motor starter is an electrical device that is used to start and stop a motor safely. Similar to a relay, the motor starter switches the power ON/OFF and unlike a relay, it also provides low voltage and overcurrent protection.

The main function of a motor starter is;

- To safely start a motor

- To safely stop a motor

- To reverse the direction of a motor

- To protect the motor from low voltage and overcurrent

Direct-On-Line (DOL) Starter Circuit Diagram

Direct-On-Line (DOL) Starter in a Pump Control Application

Similarities and Differences of VFDs and Motor Starters

Both VFDs and Motor Starters serve as the control circuit between the HMI (Human Machine Interface) and the motor. Both are also used as a means of controlling and managing the flow of electricity from the power supply and circuit breakers to the physical motor itself.

The main difference between VFDs and Motor Starters is the VFDs ability to be programmable, functioning in a solid state and having a large variety of applications. VFDs also allow for coordinated starting, stopping and speed of multiple electric motors, such as those found in a paper mill.

Torque and Current

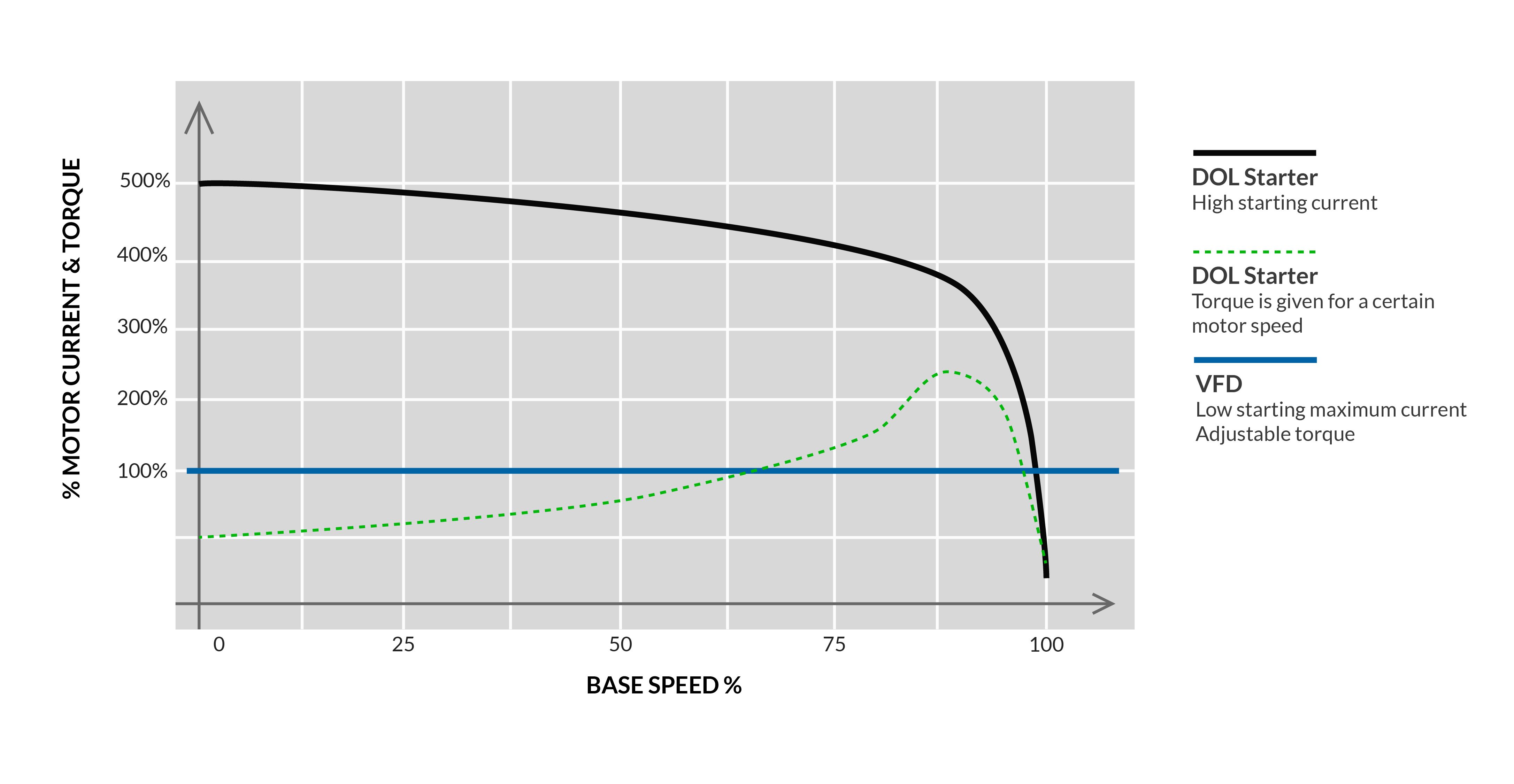

With a VFD, the torque is constant across the speed range and requires a lower starting current. A DOL starter requires much more current to start the motor and the torque varies with motor speed.

As you can see in the graph below, the amount of current needed to start the motor (inrush current) can be 500% or higher than the operating current when using a DOL starter. This is why a DOL starter is typically limited to lower horsepower applications, 5 HP and below.

Motor Starting Current

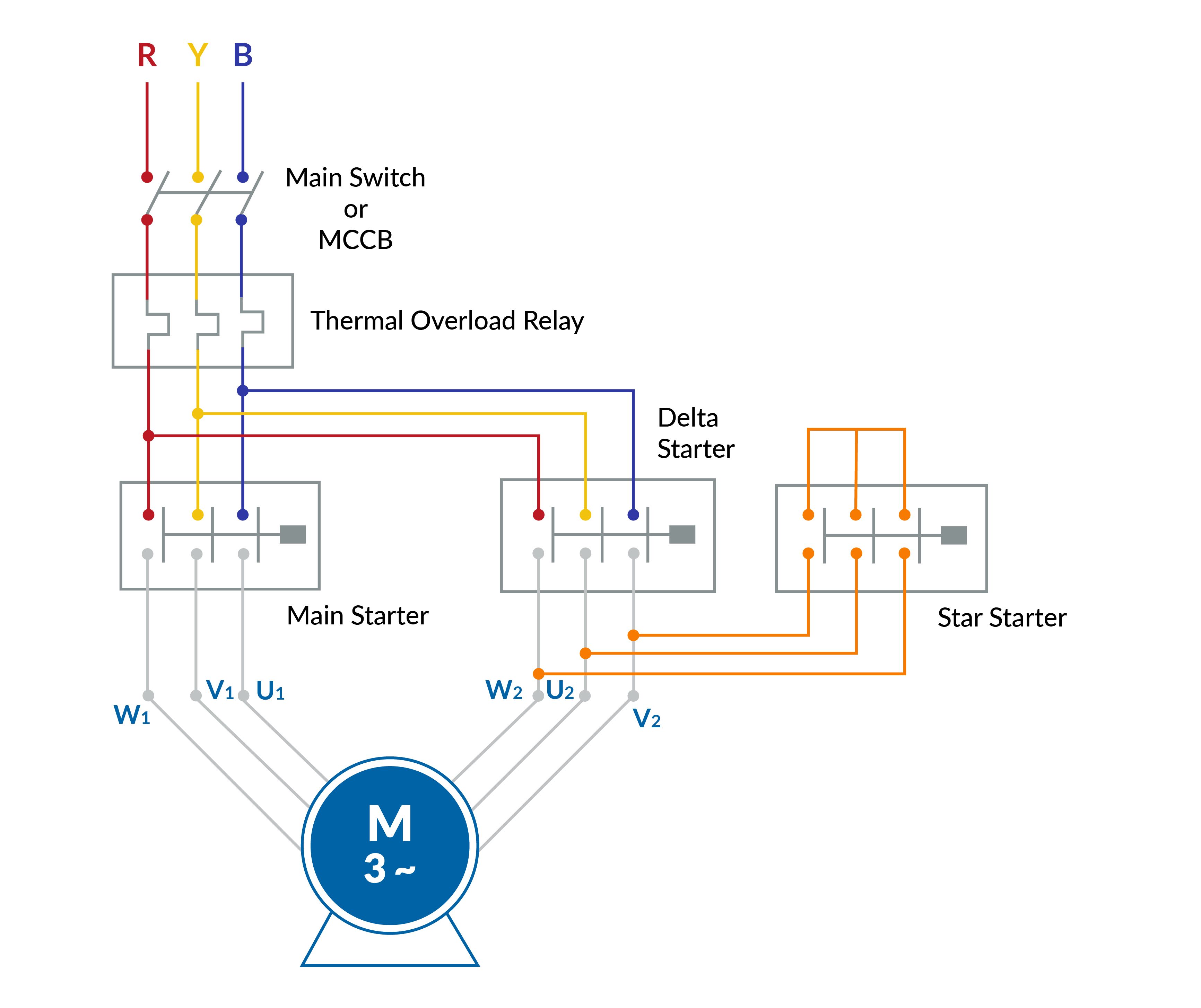

Star-Delta Motor Starter

For higher horsepower applications, inrush current can be reduced by using a Star-Delta configuration for a three-phase induction motor. Star-Delta starters are particularly suited for high inertias, where the loads are initiated after full load speed. With Star-Delta, inrush current is reduced by 33%.

Star-Delta Circuit Diagram

Soft Starter Defined

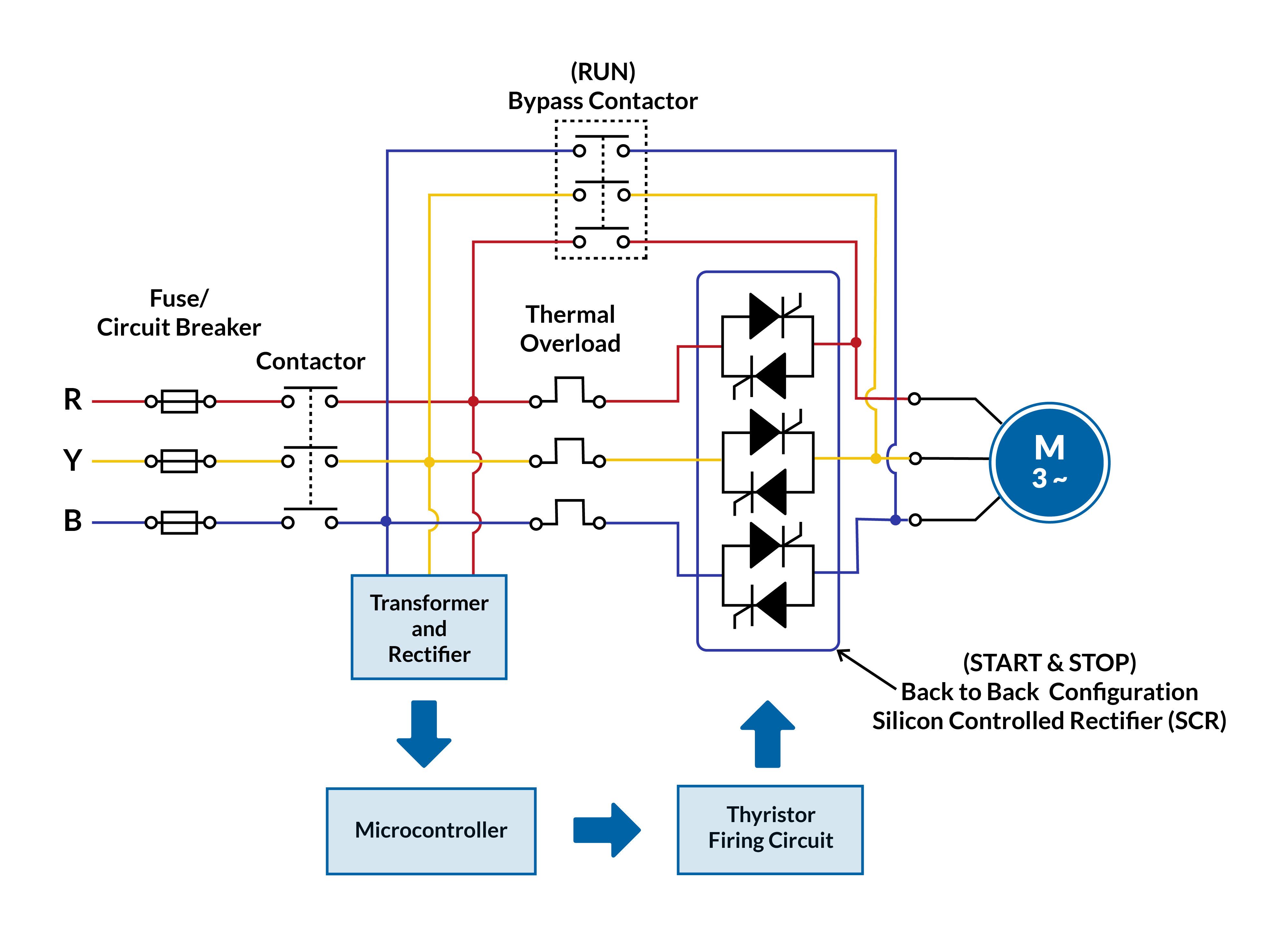

The soft starter is a type of motor starter that uses the voltage reduction technique to reduce the voltage during the starting of the motor.

The soft starter offers a gradual increase in the voltage during the motor startup. This will allow the motor to slowly accelerate and gain speed in a smooth fashion. It prevents any mechanical tear and jerking due to sudden supplying of full voltage.

But how exactly does this work to reduce inrush current? Soft starters use semiconductor thyristors to control the supplied voltage. A pair of thyristors is used in a back-to-back formation to control current flow in both directions. In a three-phase soft starter, six thyristors are used to offer voltage reduction in all three phases simultaneously.

During motor stopping, the supply voltage is gradually reduced to smoothly decelerate the motor. Once the speed reaches zero, it breaks the input voltage supply to the motor.

Because it is an intelligent device, a soft starter can also allow for connectivity to factory control and communication networks.

The Soft Starter is useful in several scenarios: to limit high inrush current, extend equipment life by reducing wear, and avoid mechanical shocks during startup. Soft starters are beneficial in industrial machinery, HVAC systems, and water treatment plants, where smooth and controlled motor starts are crucial to prevent damage and ensure reliable operation.

-Source: electricaltechnology.org

Soft Starter Circuit Diagram

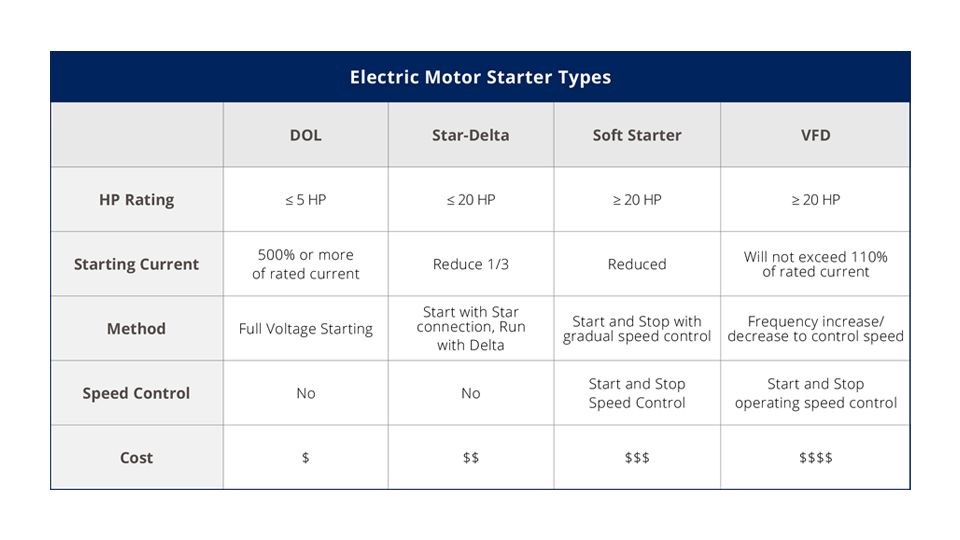

Electric Motor Starter Choices

VFDs are used to run an AC Motor at variable speeds, or for smooth start up via slower acceleration. VFDs convert 3 phase AC to DC via diodes, then the DC power gets sent to a capacitor, which is finally converted back to AC power via transistors (or “switches”). These switches are used to adjust the frequency that the VFD supplies to the motor, which controls the speed (RPM). VFDs are widely used to regulate water flow at a water treatment plant, allowing more control over the flow of the pump.

A Motor Starter is an electro-mechanical system that typically provides the motor switching and thermal overload protection. There are also Combination Motor Controllers that provide additional functions, such as motor disconnecting means, motor branch circuit, short circuit, and ground fault protection, in addition to the motor switching and thermal protection. A DOL Starter is a good option for smaller motors, typically below 5HP. For larger motors, a Star-Delta configuration should be used.

A Soft Starter is a step above a Star-Delta configuration for applications with frequent stops and starts, larger motors, and applications that need tighter integration with the factory control system. But, sourcing a soft starter can be as difficult as a VFD, so it may not be a solution for you.

Can I Use a Standard Electric Motor Starter in Place of a VFD?

Returning to our question, “Can I use a standard electric motor starter in place of a VFD?”. The answer is a definite “Yes,” with thoughtful planning and an understanding of the possible limitations.

Contact c3controls at 724.775.7926, and we can help you get started.

----------------------------------------

Disclaimer:

The content provided is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project.

Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information was posted with reasonable care and attention. However, it is possible that some information is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this article.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009