Introduction

Agricultural irrigation is essential for global food production, enabling farmers to maintain crop yields despite unpredictable weather conditions. At the heart of modern irrigation systems are pumps, responsible for delivering water efficiently to fields. The effectiveness of these pumps is greatly enhanced by industrial electrical controls, which provide automation, efficiency, and reliability. This white paper explores the various types of industrial electrical controls used in irrigation pump systems, from basic configurations to advanced solutions integrating IoT and smart technologies.

Basics of Pump Control for Irrigation

Importance of Pump Control

Pumps are essential for moving water from sources such as wells, reservoirs, or rivers to irrigation systems. Effective control of these pumps ensures:

- Energy efficiency: Reducing power consumption while maintaining water delivery.

- Operational reliability: Preventing pump failures and reducing downtime.

- Consistent water distribution: Ensuring adequate supply to different irrigation zones.

Manual Control Systems

Historically, irrigation pumps were operated manually using simple switchgear. This method required operators to start and stop pumps manually.

Key Components of Manual Control Systems:

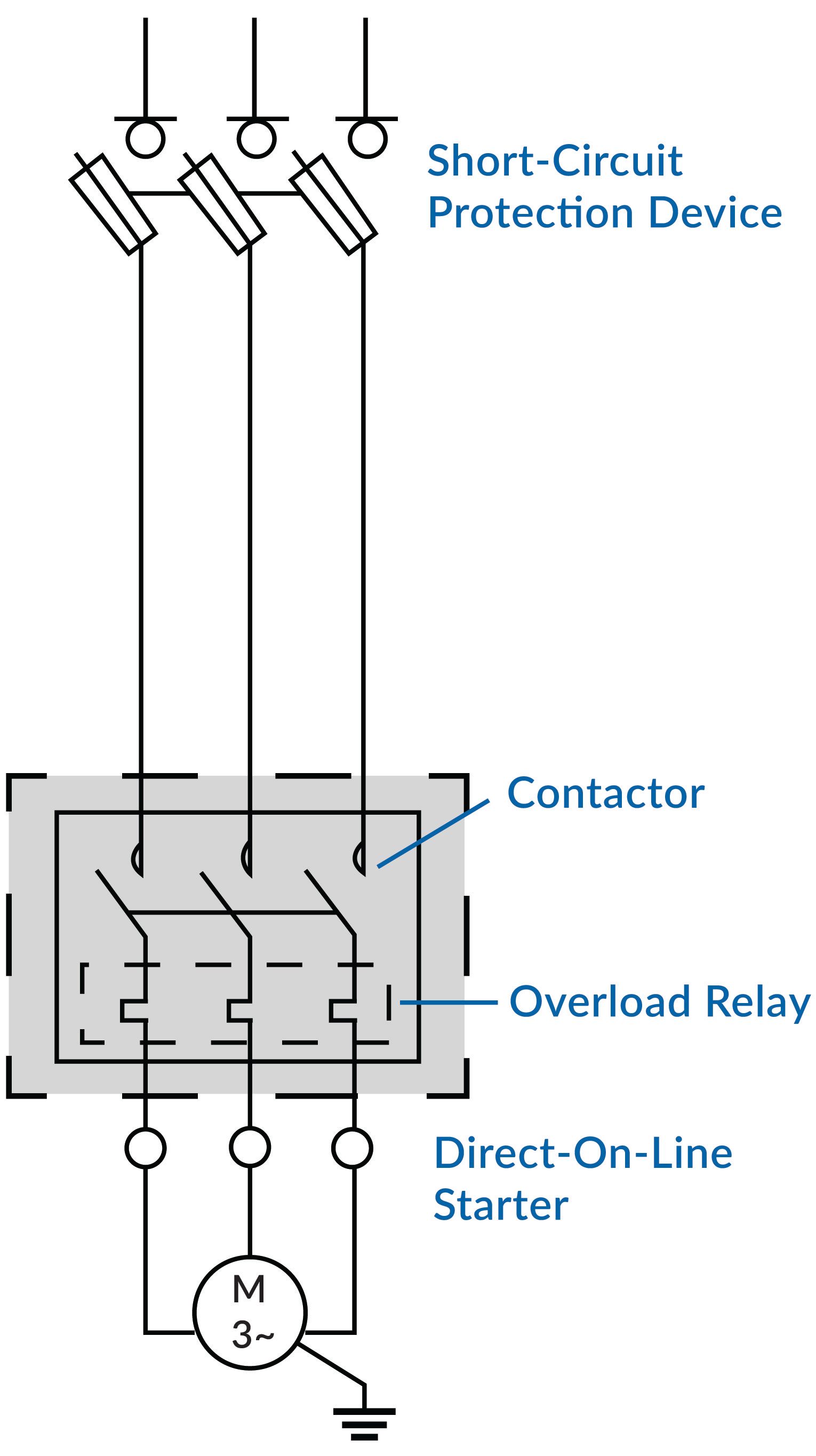

- Motor starters (Direct-On-Line, Star-Delta)

- Electromechanical relays

- Basic overload protection

- Manual switches

Even with the advances in irrigation pump control, the majority of irrigation systems continue to rely on standard control components due to their easeof use, wide availability and low down time.

Intermediate Pump Control Systems

Electromechanical Controls and Timer-Based Systems

As irrigation needs evolved, electromechanical control systems introduced automation through timers and pressure switches. These systems offered scheduled operation, reducing the need for manual intervention.

Features and Benefits:

- Pre-set operating times reduce labor costs.

- Pressure switches prevent over-pressurization and protect piping infrastructure.

- Thermal overload protection enhances motor longevity.

Basic Programmable Logic Controller (PLC) Systems

PLC-based control systems allow for more dynamic operation and better adaptability to changing irrigation demands. These systems can integrate with moisture sensors and flow meters, optimizing water use.

Advantages of PLC-Based Control:

- Customizable logic for various irrigation cycles.

- Integration with soil moisture sensors for demand-based irrigation.

- Alarm monitoring for quick troubleshooting.

Advanced Industrial Electrical Control Systems

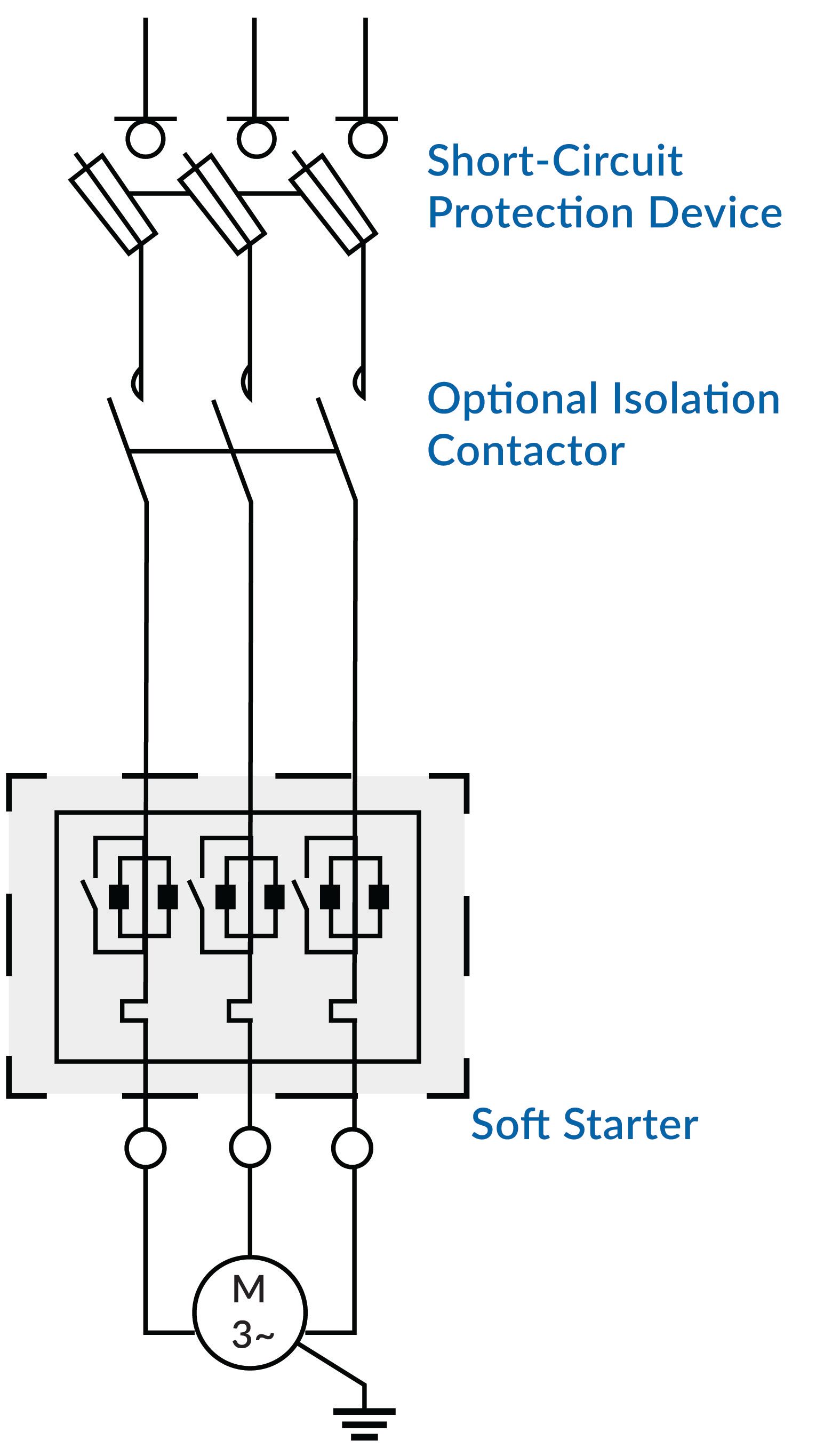

Soft Starters in Pump Control

Soft starters are used to reduce the inrush current and mechanical stress on irrigation pumps during startup. Instead of applying full voltage immediately, a soft starter gradually increases the voltage to the motor, allowing a smooth acceleration.

Key Benefits of Soft Starters:

- Prevents water hammer effects by reducing sudden pressure surges.

- Extends pump and motor lifespan by minimizing electrical and mechanical stress.

- Reduces peak demand charges, lowering energy costs.

- Protects against sudden voltage drops that could affect other electrical systems.

Soft starters are particularly beneficial for irrigation systems using high-power pumps that do not require variable speed operation but still need a controlled startup.

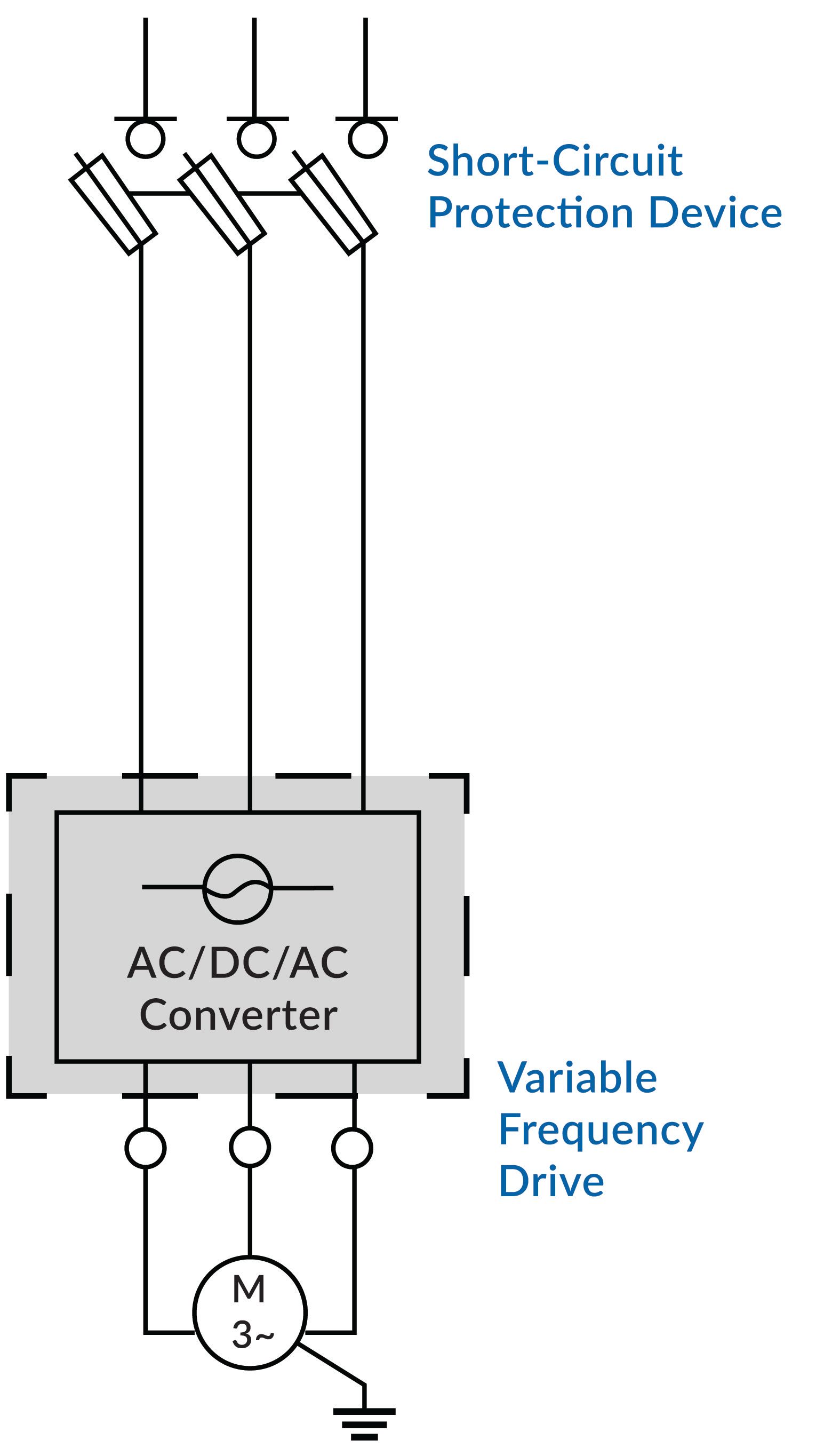

Variable Frequency Drives (VFDs) in Pump Control

VFDs are widely used in modern irrigation pump systems to regulate motor speed based on real-time water demand. They significantly reduce energy consumption by eliminating the need for throttling valves.

Key Benefits of VFDs:

- Soft start capability prevents water hammer effects.

- Energy savings by adjusting motor speed according to demand.

- Extended pump and motor life due to reduced mechanical stress.

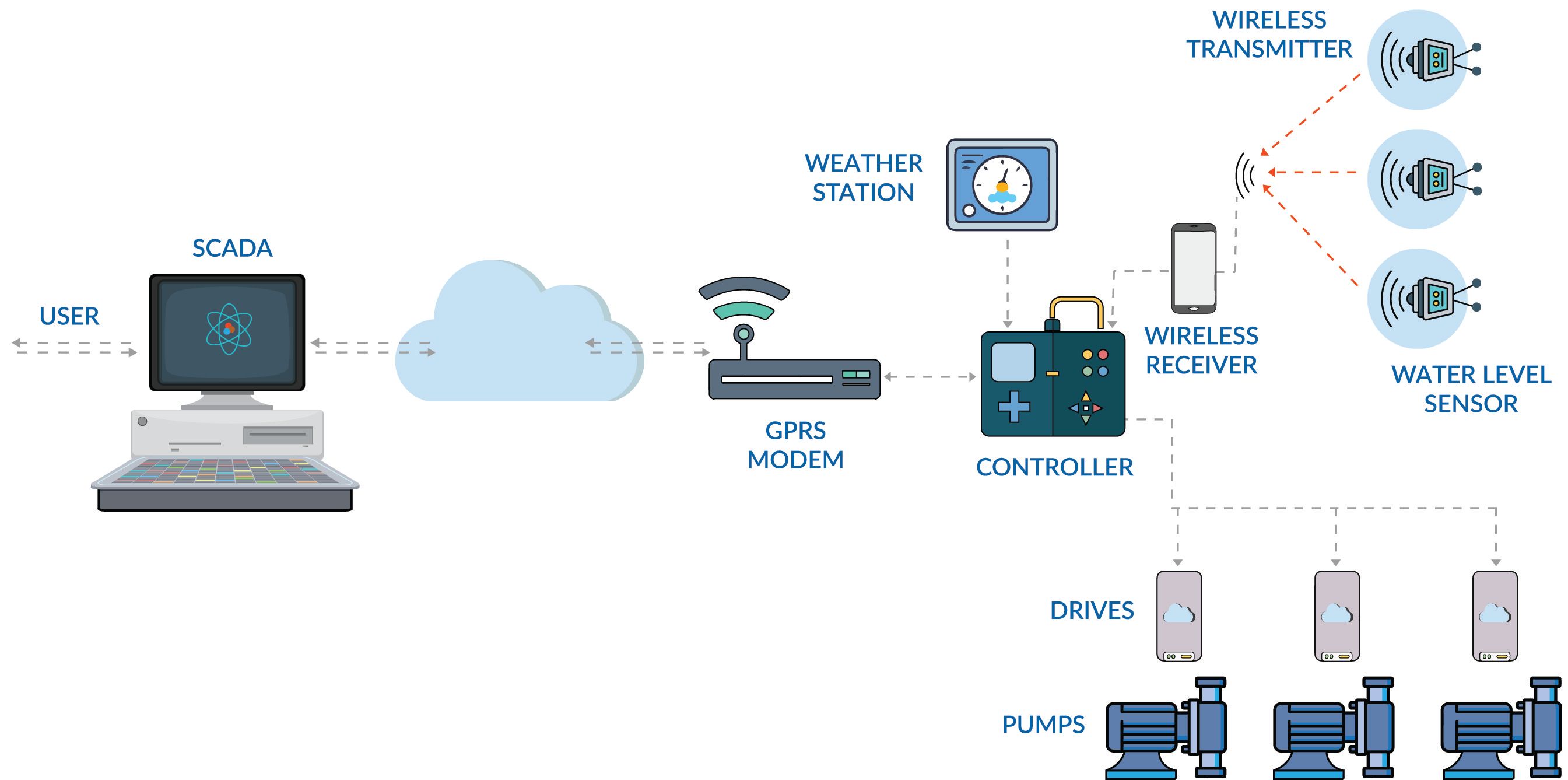

SCADA Systems for Remote Monitoring

Supervisory Control and Data Acquisition (SCADA) systems allow operators to monitor and control irrigation pumps remotely via a centralized interface.

SCADA Features in Irrigation:

- Real-time monitoring of pump performance and water levels.

- Remote start/stop capabilities reduce on-site labor.

- Historical data logging for performance analysis.

IoT and Smart Irrigation Controls

The integration of the Internet of Things (IoT) in irrigation pump control has brought about unprecedented automation and efficiency. Smart irrigation systems utilize cloud-based analytics to optimize water usage based on weather forecasts and soil conditions.

Innovative Technologies:

- Wireless sensors for real-time soil moisture and weather data.

- AI-driven predictive maintenance for early fault detection.

- Mobile app integration for remote access and control.

AI in Agricultural Irrigation Systems

Artificial Intelligence (AI) is playing a transformative role in modern irrigation systems, improving efficiency, resource conservation, and crop yield through data-driven decision-making.

AI-Driven Irrigation Optimization

- AI analyzes weather patterns, soil moisture levels, and crop water requirements to determine the ideal irrigation schedule.

- Reduces water waste by ensuring irrigation occurs only when necessary.

- Adapts irrigation strategies dynamically based on real-time environmental changes.

AI-Powered Predictive Maintenance

- Machine learning models analyze pump and motor performance data to predict failures before they occur.

- Helps reduce unexpected downtime and maintenance costs.

- Enhances system reliability by allowing proactive servicing.

AI and Remote Sensing for Precision Irrigation

- Uses satellite imagery and drone-based monitoring to assess crop health and water distribution.

- Identifies over-irrigated and under-irrigated areas to optimize water delivery.

- Integrates with SCADA and IoT sensors to automate adjustments in real-time.

AI and Energy Efficiency

- AI optimizes pump operation by analyzing energy consumption patterns.

- Works in conjunction with VFDs to reduce energy waste during off-peak hours.

- Lowers operational costs while maintaining consistent irrigation performance.

Case Studies and Real-World Applications

Energy Efficiency Improvement with VFDs

A large-scale farm in California implemented VFDs in its irrigation system, resulting in a 30% reduction in energy costs while maintaining consistent water distribution.

SCADA System Implementation for Large-Scale Irrigation

A commercial greenhouse in Florida integrated a SCADA system, allowing remote monitoring and reducing water waste by 25%.

AI-Enabled Smart Irrigation Success Story

An IoT-enabled irrigation system in Australia utilized real-time weather data and AI-driven soil sensors, improving water efficiency by 40% and boosting crop yields.

Future Trends in Pump Control for Irrigation

AI and Machine Learning Integration

Advanced AI algorithms are being used to analyze irrigation data and predict optimal water usage patterns, further improving efficiency.

Renewable Energy Integration

Solar-powered irrigation pumps combined with smart controllers are becoming a sustainable solution for remote agricultural areas.

Advanced Cybersecurity Measures

With increased connectivity, ensuring cybersecurity in SCADA and IoT-based irrigation systems is crucial to prevent cyber threats and unauthorized access.

Conclusion

The evolution of industrial electrical controls has transformed irrigation pump control from manual systems to highly automated, efficient solutions. Whether through the use of soft starters for controlled startups, VFDs for energy savings, SCADA for remote monitoring, or AI-driven irrigation optimization, modern irrigation control systems enable farmers to optimize water use, reduce operational costs, and improve agricultural productivity.

c3controls is helping overcome the evolving demands of the industry. For almost 50 years, c3controls has specialized in manufacturing high-quality electrical controls for pump control and irrigation control systems. With over seventeen million product configurations and a complete UL508A panel shop, c3controls is ready to help you enhance your agricultural productivity. Download our Guide to Control Components for Agricultural Equipment, or contact us today!

References

- U.S. Department of Agriculture (USDA) - Irrigation and Water Use: https://www.ers.usda.gov/topics/farm-practices-management/irrigation-water-use/

- International Commission on Irrigation and Drainage (ICID) - Pumping and Energy Use in Irrigation: https://www.icid.org/

- IEEE Xplore - Smart Irrigation and IoT Integration: https://ieeexplore.ieee.org/

- Environmental Protection Agency (EPA) - Water Efficiency and Pump Systems: https://www.epa.gov/

- National Renewable Energy Laboratory (NREL) - Solar-Powered Irrigation: https://www.nrelgov/

----------------------------------------

Disclaimer:

The content provided is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information was posted with reasonable care and attention. However, it is possible that some information is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this article.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009