Many advanced technologies are changing our lives every day. The advent and growth of the Electric Vehicle (EV) is a major example of just how much those changes can mean for our business life — and for our personal lives.

Technological advances and environmental regulatory pressures on internal combustion engine (ICE) vehicles are driving the expanding interest in the EV market. Many established automobile manufacturers are introducing new EV models, alongside new start-ups entering the market. With the selection of makes and models available today, and many more to come, the possibility that we all may be driving EVs in the future is closer to reality than ever.

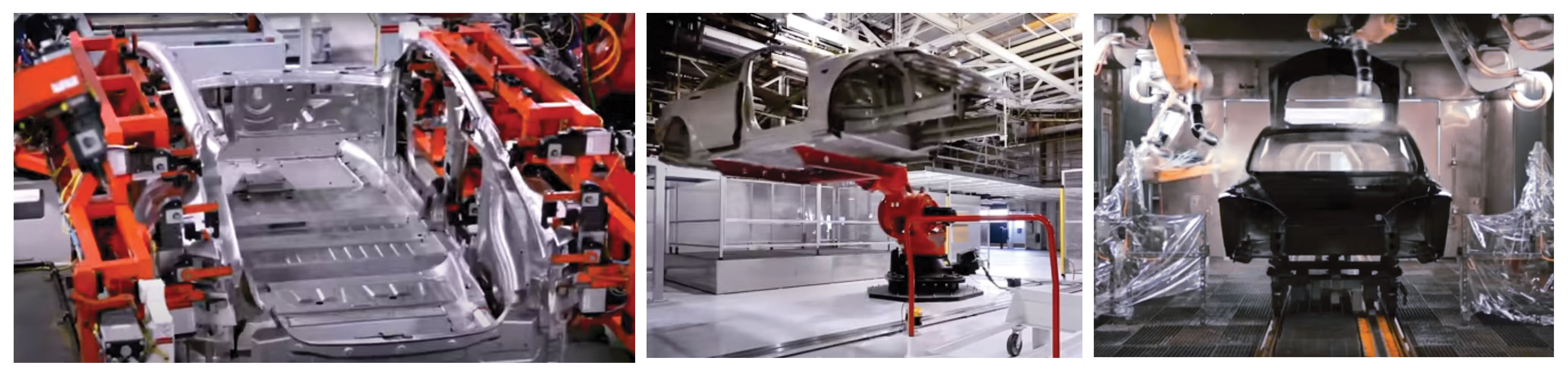

The technology that powers the EVs of today demands many changes from the way traditional vehicles have been manufactured. The process to build EVs requires nearly as much design consideration as the aesthetics of the vehicle itself. That includes a stationary line of robots specifically designed for EV applications — as well as flexible production lines with mobile robots that can be moved in and out at various points of the line as needed.

In this issue we will examine what changes are needed to efficiently design and manufacture EVs today. We will talk about how processes and production procedures differ from those used to manufacture gas-powered vehicles.

Design, components and manufacturing processes

Although the development of the EV was vigorously pursued by researchers and manufacturers in the early twentieth century, interest was stalled due to cheaper cost, mass-produced gasoline-powered vehicles. Research waned from 1920 until the early 1960s when environmental issues of pollution and the fear of depleting natural resources created the need for a more environmentally friendly method of personal transportation.

EV design

Today’s EVs are very different from ICE (internal combustion engine) gasoline-powered vehicles. The new breed of EVs has benefited from a series of failed attempts to design and build electric vehicles using traditional methods of production used by manufacturers for decades.

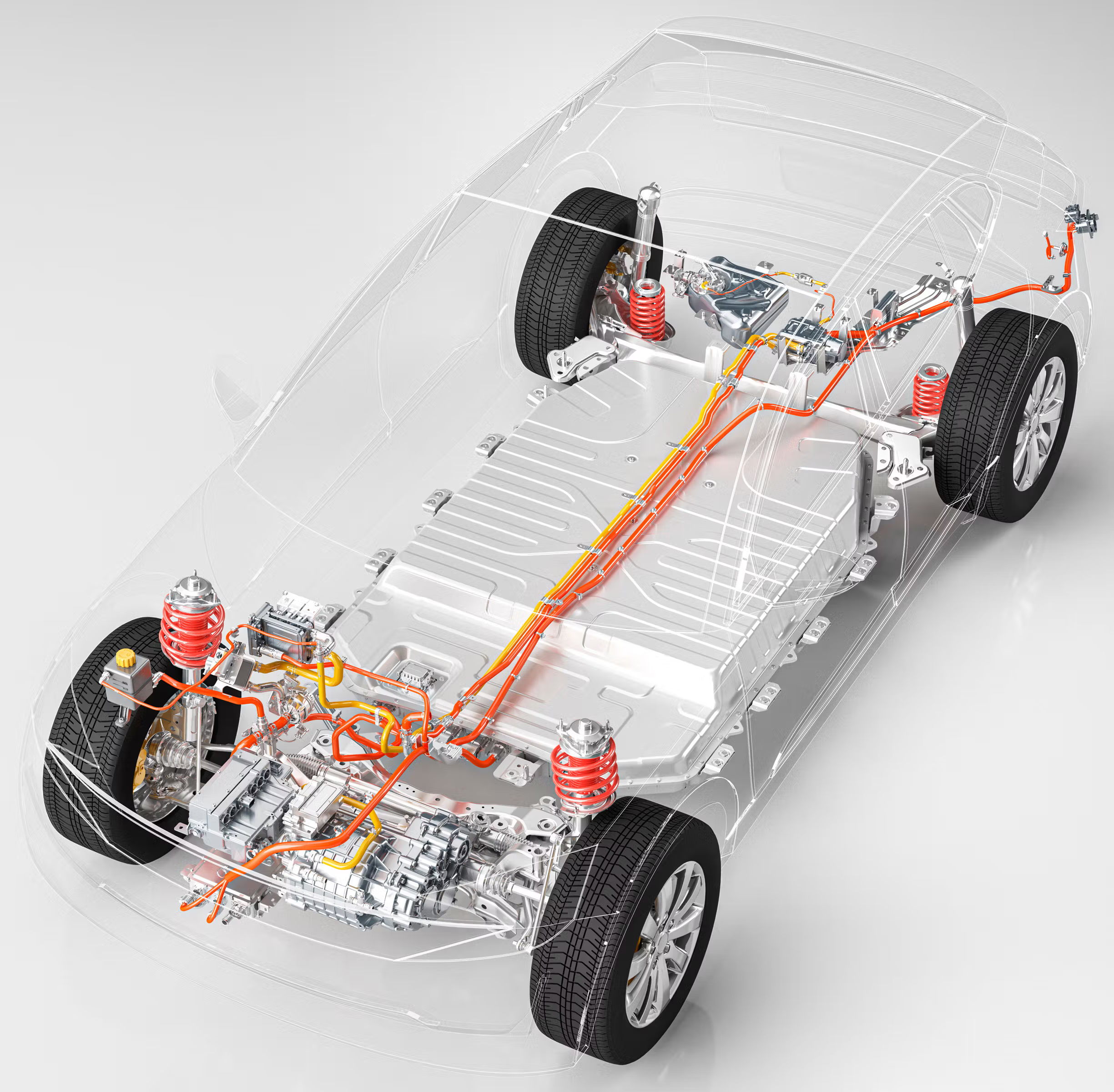

There are numerous differences in how EVs are manufactured when compared to ICE vehicles. The focus used to be on protecting the engine, but this focus has now shifted to protecting the batteries in manufacturing an EV. Automotive designers and engineers are completely rethinking the design of EVs, as well as creating new production and assembly methods to build them. They are now designing an EV from the ground up with heavy consideration to aerodynamics, weight and other energy efficiencies.

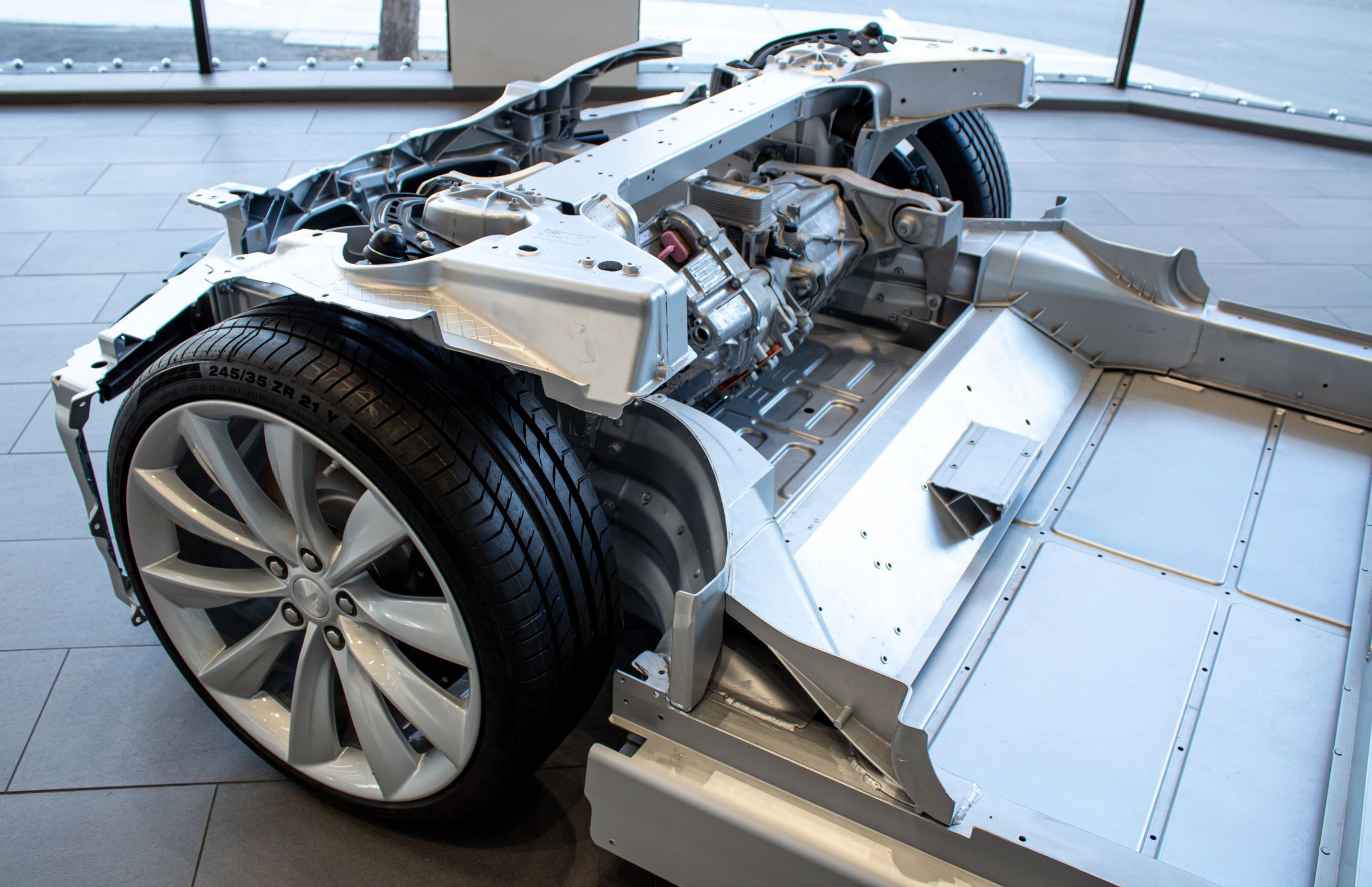

- The single biggest modification of the car is the underbody. While this structure has been very similar in the past, with EVs there is no engine and there are no exhaust systems needed. There is an aerodynamically designed full belly pan under the EV that contains trays where the battery pack is placed. With more and more variations and shapes of battery packs available for different models, the challenge is to be able to make these variations on one Flexible Manufacturing System (FMS). Since all EV battery cells are quite heavy, flexible robotic lines are necessary.

- In addition, FMS production lines must accommodate many new robotically performed joining methods. In many instances spot welding is being replaced by an increased use of self-piercing rivets, gluing, sealing, flow drilling, and laser welding — and are specifically chosen depending on the tray used for each particular type of battery cell.

- The EV’s inner structure is called a “space frame” and is made of strong, lightweight aluminum — and for additional weight-savings, the wheels are also made of aluminum instead of steel. Using manufacturers molds, these aluminum parts are poured at a foundry. In addition, the steering wheel and seat frames are made of magnesium, a strong, lightweight metal. Even the body panels are made of lightweight aluminum, or an impact-resistant composite plastic. Both materials are recyclable, providing long-term disposal advantages.

- In an effort to reduce weight, the structural frame, seat frames, wheels and body are designed for high-strength, safety — and the lightest possible weight. New configurations have been developed that provide support for the components and protection of the vehicle occupants with minimal mass and use of high-tech materials, including aluminum, magnesium and advanced composite plastics.

- The windshield is solar glass that keeps the interior from overheating in the sun and frost from forming in winter. Materials that provide thermal conservation reduce the energy drain that heating and air conditioning impose on the batteries.

- Some features did have to be eliminated or changed while leaving all the comforts drivers find desirable and adding new considerations as well. One feature that was removed because of space restrictions was the spare tire. This was possible because the EV tires contain a sealant to repair any leaks automatically. In addition, the tires are rubber and designed to inflate to higher pressures, so the car rolls with less resistance to conserve energy.

- An added safety consideration was a pedestrian warning system, because EVs run so quietly that pedestrians may not hear them approach. Driver activated flashing lights and beeps warn pedestrians that the car is approaching. This system works automatically when the car is put in reverse as well.

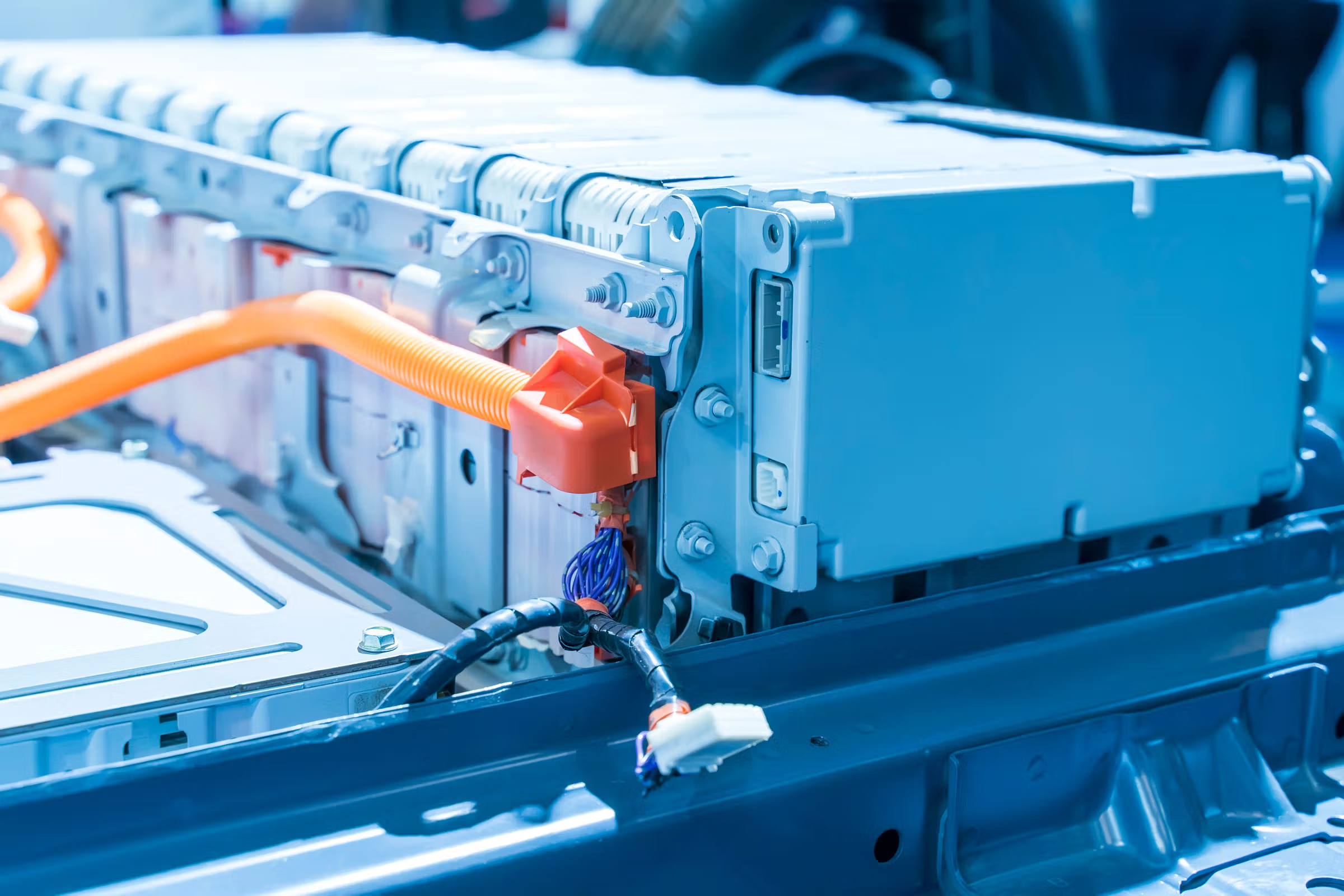

EV battery

An electric vehicle battery (EVB) is the standard designation for batteries used to power electric motors of all types of EVs. In most cases, these are rechargeable lithium-ion batteries that are specifically designed for a high ampere-hour (or kilowatthour) capacity. Rechargeable batteries of lithiumion technology are plastic housings that contain metal anodes and cathodes. Lithium-ion batteries use polymer electrolyte instead of a liquid electrolyte. High conductivity semisolid (gel) polymers form this electrolyte.

Lithium-ion EV batteries are deep-cycle batteries designed to give power over sustained periods of time. Smaller and lighter, the lithium-ion batteries are desirable because they reduce the weight of the vehicle and therefore improve its performance.

These batteries provide higher specific energy than other lithium battery types. They are typically used in applications where weight is a critical feature, such as mobile devices, radio-controlled aircraft and, now, EVs. A typical lithium-ion battery can store 150 watt-hours of electricity in a battery weighing approximately 1 kilogram.

In the last two decades advances in lithium-ion battery technology has been driven by demands from portable electronics, laptop computers, mobile phones, power tools and more. The EV industry has reaped the benefits of these advances both in performance and energy density. Unlike other battery chemistries, lithium-ion batteries can be discharged and recharged daily and at any level of charge.

There are technologies that support the creation of other types of lighter weight, reliable, cost effective batteries — and research continues to reduce the number of batteries needed for today’s EVs. Batteries that store energy and power the electric motors have evolved into a technology of their own and are changing almost every day.

Traction system

EVs have electric motors, also referred to as the traction or propulsion system — and have metal and plastic parts that never need lubrication. The system converts electrical energy from the battery and transmits it to the drive train.

EVs can be designed with two-wheel or all-wheel propulsion, using either two or four electric motors respectively. Both direct current (DC) and alternating current (AC) motors are being used in these traction or propulsion systems for EVs. AC motors are currently more popular, because they do not use brushes and require less maintenance.

EV controller

EV motors also include a sophisticated electronics controller. This controller houses the electronics package that operates between the batteries and the electric motor to control the vehicle speed and acceleration, much like a carburetor does in a gasoline-powered vehicle. These on-board computer systems not only start the car, but also operates doors, windows, air conditioning, tire-pressure monitoring system, entertainment system, and many other features common to all cars.

The controller regulates energy flow from the battery to the motors and allows for adjustable speed. Specially designed Silicon-Controlled Rectifiers (SCRs) are used for this controller. They allow full power to go from the battery to the motor but in pulses, so the battery is not overworked, and the motors are not underpowered.

The controller transforms the battery’s direct current (DC) into alternating current (AC) and regulates the energy flow from the battery. The controller will also reverse the motor rotation — putting the vehicle in reverse — and converting the motor to generators, so that the kinetic energy of motion can be used to recharge the battery when the brake is applied.

EV brakes

Any type of brake can be used on EVs, but regenerative braking systems are preferred in electric vehicles. Regenerative braking is a process by which the motor is used as a generator to recharge the batteries when the vehicle is slowing down. These braking systems recapture some of the energy lost during braking and channel it back to the battery system.

During regenerative braking, some of the kinetic energy normally absorbed by the brakes and turned into heat is converted to electricity by the controller — and is used to re-charge the batteries. Regenerative braking not only increases the range of an electric vehicle by 5 to 10%, but it also has proven to decrease brake wear and reduce maintenance cost.

EV chargers

Two types of chargers are needed. A full-size charger for installation in a garage is needed to recharge EVs overnight, as well as a portable recharger. Portable chargers are quickly becoming standard equipment from many manufacturers. These chargers are kept in the trunk so the EVs’ batteries can be partially or completely recharged during a long trip or in an emergency like a power outage. In a future issue we will further detail the types of EV charging stations such as Level 1, Level 2 and Wireless.

Manufacturing process

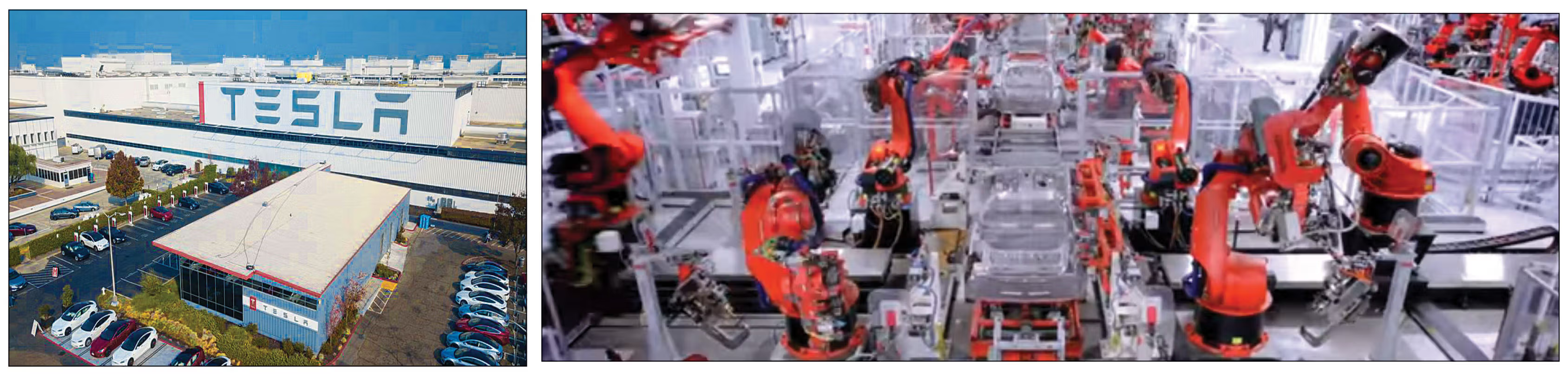

Automotive engineers, as well as manufacturing professionals, have given the EV manufacturing process as much design consideration as the overall design of the vehicle itself. To illustrate how EV manufacturing can be successfully accomplished we’ve taken a brief look at how Tesla builds its EVs using many high-tech robotic approaches.

Tesla’s goal to sell 20 million vehicles by 2030 will undoubtedly be realized. With EV sales projected to hit 300 million by 2030, Tesla and other manufacturers will be working at a break-neck pace to meet consumer demand.

First US electric-only automotive manufacturer

Tesla, the first truly new US automotive manufacturer in 90 years, is the biggest electric-only car company — delivering over 936,000 vehicles globally in 2021 alone with a market cap of $948 billion. Tesla is one of the best examples of the philosophies and technologies being employed in the everwidening electric car manufacturing world.

In 2010, Tesla acquired New United Motor Manufacturing Inc (NUMMI), a former GM and Toyota manufacturing plant in Freemont, CA. The ceilings and columns where painted white and skylights were added to brighten and bring natural light into the plant. The psychology of this makeover is that if you want quality, you need people to feel at ease and to feel like they work in a quality place.

By June 2012, the first Model S rolled off the line. In some ways Tesla’s Freemont plant harkens back to the Ford River Rouge plant, which in 1927 had the distinction of “ore to assembly” of the Model A. While other manufacturers may use a network of suppliers to produce many of their sub-assemblies and components, Tesla does much of its manufacturing in house. (They like to keep “Everything Under Control” too.)

Body assembly

The body assembly process begins with coils of aluminum of different gauges, which are uncoiled into a blanking machine that flattens the metal into blanks. The blanks are then fed into an enormous stamping press. At this stage, large custom-made dies form the body panels, which are then transported to the body center.

This is where the EV begins to be assembled — starting with the underbody, which is the main floor system of the EV where the batteries are seated. The body sides are then added to provide internal reinforcement as well as the outer skin. Inside the framing is where the body sides, the underbody and the front end of the vehicle are all married together.

One of the most unique things about the body center is that there are five different overall joining methods for the body shell, including adhesive, self-piercing rivets and cold metal transfer, as well as conventional resistance welding and a delta spot welding system. When the body leaves the body center it is a fully completed body shell — ready to be prepped and painted.

Paint shop

A Kuka robot places the body onto a conveyor that transports it to the paint shop where multiple pretreatment primer base coats are applied. Specially designed paint robots work in an extremely clean environment to produce a beautifully painted body, ready for general assembly. At this point, each EV moves through the factory autonomously powered by its propulsion system and batteries. Since the EV has no internal combustion engine there is no potential danger of exhaust fumes as it travels to the general assembly area.

General assembly

The Tesla EV is assembled from inside out. Automation is used to the fullest — as the same robot that installs the seats, then changes tools to position the windshield, apply adhesive and seat it on the vehicle. In total, about 1,000 robots perform very diverse tasks in the production of the Model 3. Since robots are extremely good at repeatability and accuracy of motion needed, employees are utilized in more flexible situations where human intelligence is required.

EV manufacturing is unique in that many of the components are completely different than for traditional ICE powered vehicles, including the drive units, battery pack, and battery modules. Many of those components did not previously exist, which required Tesla to build them. However, there are also thousands of fewer components in an EV, so it only takes about two days for a Tesla Model 3 to go from raw material to a completed vehicle.

Quality control

Every part used in the operation of the EV has been tested during the many assembly steps at the production line. After the battery pack and propulsion unit have been installed, the car can be driven inside the plant. This shows that the EV is working several steps before it is completed. Due to the individual quality checks at each stage of assembly, the only major quality control requirements are a comprehensive set of tests and inspections.

Limited byproducts or waste

There are limited byproducts from the manufacture of electric cars — and waste in the assembly factory is minimal to nonexistent. Parts, components and subassemblies are made elsewhere and delivered to the assembly plants. Trimmings and other waste are recaptured during manufacturing and most are recyclable.

The future

EVs are critically important to the future of the automotive industry and to the protection of the environment. Ultimately, what form the electric vehicle will take and its total acceptance by the public are still uncertain. Consumption of decreasing fossil fuels and concerns over air and noise pollution are major issues today. The costs of the energy being consumed — and pollution caused by the complications of recycling gasoline-powered cars — are both driving forces that are leading the success of the electric car.

There are several things that are certain. The EV industry is here to stay — and the list of EV manufacturers will continue to grow. New and better technologies will continue to be developed — and charging methods will improve and be faster. As the EV market grows in the US and worldwide, the positive effects of moving to electric vehicles will be reflected in the environment and our everyday lives for years to come.

Electrical machine controls for over four decades

We hope you have benefited from this issue of EVERYTHING UNDER CONTROL and that you have learned a little more about how today’s EVs are designed and manufactured. There are many industries and companies that will play a part in the ever growing EV market. The adoption of EVs will not only help the US economy, but will advance the efforts to reduce pollution in our country.

In future issues, we will present information on the latest trends and advancements for a wide variety of industries that depend on c3controls products as an integral part of their machine controls.

----------

Check out the other articles in this Series on Electric Vehicles - New Trends in Technology.

----------------------------------------

Disclaimer:

The content provided is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information was posted with reasonable care and attention. However, it is possible that some information is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this article.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009