If you require industrial electrical controls for automation purposes, browse our online shop or download our catalog.

Introduction

Within logistics as a whole lives the cumbersome process known as reverse logistics. Reverse logistics has long been a neglected area. However, growing market pressures, such as online retail and customer expectations, are increasing the strain on this area of supply chains.

In order to stay competitive (and even profitable), it is crucial that companies carry out innovation in this area and adapt to shifting market demands.

Thanks to the far-reaching effect this often ‘pushed-under-the-rug’ supply chain sector has, anybody who is involved in management or entrepreneurship can benefit by becoming familiar with reverse logistics.

So, what is reverse logistics?

In this article, we will review what reverse logistics consists of, the existing key issues and hidden costs associated with it, as well as it’s undeniable value and possible innovations and changes that can be made in reverse logistics processes.

Read on to familiarize yourself with one of the trickiest (yet vital) segments of supply chains.

Reverse Logistics Definition

Reverse logistics comprises of the sector of supply chains that process anything returning inwards through the supply chain or traveling ‘backward’ through the supply chain. Hence the name reverse logistics.

This can encompass anything from returned goods, inward disposal/recycling of packaging materials, the recycling/responsible disposal of materials from previously sold products, etc.

The full definition of reverse logistics, as according to The Council of Logistics Management, is the process of implementing, controlling, and planning the cost-effective flow of finished goods, raw materials, and in-process inventory. The flow is from the point of consumption (i.e. the customer) to the point of origin (i.e. the manufacturer), to properly dispose of these or to recapture value.

Included in this definition is any re-manufacturing or refurbishment of goods.

Some reverse logistics examples are:

- Return of goods by customers

- Return of unsold goods by distribution partners due to contract terms

- Re-use of packaging

- Refurbishment of goods

- Repairs and maintenance as per guarantee agreements

- Re-manufacturing of goods from returned or defective items

- Selling of goods to a secondary market in response to returns or overstocking

- Recycling and disposal of end-of-life goods

Existing and growing market dynamics, such as higher customer return rates and a need for recycling and re-use, are increasing the occurrence of these instances of reverse logistics.

Incorporating lean principles into reverse logistics not only addresses these market dynamics but also enhances the overall efficiency of the supply chain. By integrating the processes of shipping and returns, a lean supply chain reduces operational redundancies and waste, making the system more streamlined and cost-effective. This integration ensures that resources are utilized optimally, leading to a sustainable business practice that can adapt to customer needs and environmental responsibilities more effectively.

Thus, a solid reverse logistic plan is essential not just for handling returns or waste, but as a strategic component that contributes to a leaner, more responsive, and efficient supply chain. This holistic approach not only supports business objectives but also aligns with broader sustainability goals, making it a critical aspect of modern supply chain management.

What Are The Five Rs of Reverse Logistics?

Reverse logistics is a crucial component of modern supply chain management. It involves the process of moving goods from their final destination back to the manufacturer or distributor for return, repair, remanufacture, recycling, or disposal. The five Rs of reverse logistics are essential principles that guide this process.

1. Returns

Returns involve the management of goods that customers send back for various reasons, such as defects, wrong items, or buyer's remorse. Efficient return policies not only boost customer satisfaction but also allow companies to recover value from returned products.

2. Recalls

Recalls are necessary when products are found to be defective or dangerous after reaching the market. Effective recall systems protect consumers and help companies minimize damage to their brand’s reputation while ensuring compliance with regulatory standards.

3. Repairs

Repairing defective products instead of discarding them can save resources and reduce waste. This step involves diagnosing faults, fixing them, and then either reselling or returning the repaired items to the customer.

4. Recycling

Recycling involves breaking down products into their raw materials for reuse in new manufacturing. This step is vital for sustainability, reducing the need for virgin materials and decreasing the overall environmental impact.

5. Repackaging

Repackaging refers to the process of refurbishing and repacking returned goods to make them suitable for resale. This can involve checking for damage, cleaning, and reboxing the items, thereby extending the product’s lifecycle.

By understanding and implementing the five Rs—Returns, Recalls, Repairs, Recycling, and Repackaging—businesses can significantly enhance their efficiency, sustainability, and customer satisfaction. These principles are essential for reducing waste, conserving resources, and adding value to both the company and its customers.

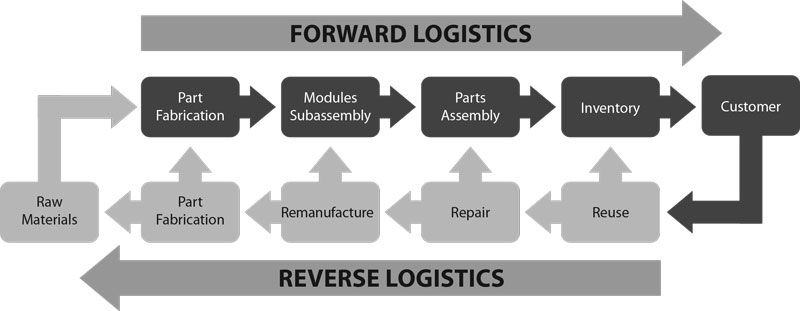

How Are Forward Logistics And Reverse Logistics Different?

Forward Logistics: This involves the journey of products from the manufacturer to the end customer. It includes all the steps required to get a product from production to the consumer's hands—such as warehousing, distribution, and delivery. Essentially, it’s the "going out" process within the supply chain.

Reverse Logistics: On the other hand, this process manages the return of products from the end customer back to the retailer or manufacturer. Common scenarios include returns due to defects, end-of-life products, or recycling efforts. It’s the "coming back" process, focusing on reclaiming value or proper disposal.

Key Differences:

- Direction: Forward logistics moves products from creation to consumption, while reverse logistics handles the flow from consumer back to the point of origin.

- Objective: Forward logistics aims to fulfill customer demand and deliver products efficiently. Reverse logistics focuses on returns, recycling, and repairing products.

- Complexity: Managing returns often involves unpredictable factors and can be more complex compared to the relatively streamlined forward logistics process.

By understanding these differences, businesses can better manage their supply chains and enhance overall efficiency.

The Unsung Value of Effective Reverse Logistics

Traditionally, reverse logistics hasn’t been anybody’s favorite area of supply chains. Often largely neglected and ignored by companies, reverse logistics departments are even today working in widely acknowledged outdated formats, utilizing things like fax machines and spreadsheets.

Back in 2001, almost 40% of participants in a published study reported stating that returns management wasn’t equally important to other areas and therefore gets less attention.

However, effective logistics processes hold an invaluable list of benefits that can provide material value and gains to most businesses.

Reverse Logistics Can Provide Valuable Product Data

One of the largest benefits of an effective reverse logistics process is that it can provide organizations with valuable product data. This is crucial for the correction of existing issues that might be causing the return of products.

Well planned and thoroughly implemented reverse logistics processes are able to easily collect data on the reason for customer returns, as well as other useful data such as common product defaults and lifespans.

Potential for Reduced Losses and Additional Revenue

Proper and streamlined management of goods and materials traveling back up the supply chain can result in reduced losses as well as additional revenue.

For example, tailored return policies and error-free returns handling can save on returns related losses. Compounding this is the fact that proper handling and distribution of returned goods can result in additional sources of revenue and reduced losses.

This additional revenue can be realized by refurbishing, repairing, and recycling goods, or selling off returned products or materials from them.

Reduced Costs

Streamlined reverse logistics processes also allow for reductions in various cost areas. These include:

- Storage costs

- Transportation/return shipping costs for both delivery and returns (i.e. some companies combine replacement shipping with return shipping to reduce transportation overheads and provide heightened levels of customer satisfaction)

- Returns labor, including processing, credit reconciliation, technical support, and vendor management

- Costs associated with fraudulent returns

These reverse logistics costs are often spread over multiple sections of the supply chain, causing them not to be addressed and minimized, as no one department or person is directly accountable for them.

By developing an efficient reverse logistics process, companies can not only reduce these costs but more accurately track and analyze them as well.

Enhanced Service

A high functioning reverse logistics department and its processes will be able to provide disappointed customers with a superior level of service upon the return of their items.

In competitive markets, this is essential, and nowadays enhanced service—especially at a critical point in the brand/customer relationship such as return processing—is even more vital. Social media sharing and customer influence online can have very material impacts on a company’s’ reputation and footing in the market.

Good Brand Image

Taking into consideration that improved reverse logistics and returns processes yield heightened levels of service and act to reduce negative publicity, it naturally follows this and can result in enhanced levels of brand image.

Brands that offer recycling for end-of-life goods also enjoy recognition for efficiency and good practices.

Apple’s reverse logistics process of providing customers with a discount on purchases when they return old devices in-store is an outstanding example of this. Not only does Apple enjoy the positive publicity that comes with this policy, but they also gain by being able to re-use parts and materials from end-of-life goods.

Customer Retention

Another highly valuable benefit of effective reverse logistics is increased customer retention. As mentioned above, things like returns and guarantee handling can be pivotal points in the customer/brand relationship.

According to published research, 95% of consumers surveyed stated that they will not buy from a brand again if they undergo a negative return experience.

By ensuring that the customer is handled well, has access to convenient and thoughtful return processes, and is not shortchanged, well-operated reverse logistics systems can substantially increase levels of customer retention.

Opportunity for Waste Reduction and Environmentally Friendly Practices

Besides the above company-specific benefits that evolved reverse logistics processes can yield, well-thought-out reverse logistics policies can also provide an all-encompassing benefit in the form of waste reduction and environmentally sustainable practices.

Methods to Optimize Reverse Logistics

Although reverse logistics has long been an under-optimized area, with the new market pressures at sway, it is even more important for companies to focus attention and resources on it than ever before.

Even though reverse logistics can be a challenging supply chain sector to improve, there exist a number of ways that companies can go about this.

Review, Revision, and Optimization of Return Policies and Vendor Agreements

A crucial step in the optimization of reverse logistics is the review of return policies as well as vendor agreements. Returns is becoming a competitive area that can differentiate one brand from another. For this reason, return policies need to stay current and be subject to periodic revision.

Is it also essential to review and update vendor agreements to optimize the reverse logistics process. This can help to reduce instances of overstocking, the return of overstock, and its associated costs and pitfalls.

In the current retail environment, lenient and attractive return processes are considered to be the most competitive option. For example, 95% of customers will make repeat purchases from a brand or company if the returns process is easy.

However, at the same time, it is important to integrate safeguards into return policies to prevent the abuse of them, as this will place a burden on the reverse logistics process.

For example, according to certain stats, up to 91% of returns are caused by overly liberal return policies that, in turn, cause customers to deliberately over order.

Therefore, crafting optimized return policies that provide value to the customer, while protecting the reverse logistics channels from becoming overburdened, is key.

Outsourcing

For some companies, the most efficient way to optimize their reverse logistics departments is to outsource the function completely.

This is a lean, nimble solution that can be implemented quickly and effectively. Depending on solution providers and situations, it can also be a cost-effective strategy. At the same time, if a company already has a robust supply chain infrastructure behind it, utilizing this for the purpose of upgraded reverse logistics might be a more cost-effective and financially wise option.

There are also a couple of potential downsides to outsourcing reverse logistics. The quality of the process is no longer under control of the brand or company, and in some cases, there isn’t room for ‘fine tweaking’ or customization.

Automation

Automation is becoming recognized as a powerful disruptor within the supply chain sector, with warehouse automation edging its way to the forefront of supply chain development. This is thanks to the ability of automation to solve a number of long-standing warehousing problems.

Automation can also be successfully applied to address a host of traditional reverse logistics issues, such as response time, forecasting, labor costs, and fraudulent returns.

If you are unfamiliar with the application of supply chain automation, in brief, it consists of hardware components such as scanners, sensors, microcontrollers, automatically guided vehicles (AVGs) and drones. Coupled with any required hardware elements are various forms of software (such as IoT and warehouse management software) that can track stock, store data, and carry out processes without human input.

Although automation costs can be high upfront, automation has the potential to drastically reduce both losses and expenses far into the future in a reverse logistics process.

This is thanks to outcomes such as better use of data, real-time inventory tracking, enhanced customer service, and the aforementioned savings on labor, transportation, and warehousing space.

Although some elements of automation can require a substantial investment, such as AVGs, other large warehousing components, and drones, other integral elements such as PLC microcontrollers are low-cost components. Software components are also relatively low in cost compared to large all-out hardware elements and are associated with an elevated RIO.

Centralized Return Centers

According to research one of the strategies implemented that has measurably optimized reverse logistics in certain use cases is the implementation of centralized return centers.

Centralized return centers (CRCs) are warehouses and centers which process only returns. They deal exclusively in the flow of goods back up the supply chain and are not concerned with forward-moving distribution, as opposed to distribution centers that deal in both distribution of goods going down the supply chain and up the supply chain.

According to companies evaluated in the above research, distribution centers don’t work well when handling goods flowing both up and down the supply chain. This is because the forward motion of products is in most cases prioritized, which causes the processing of reverse logistics to suffer.

What is Reverse Distribution?

Reverse distribution involves the process of collecting and removing products that are unsold, damaged, expired, or recalled from retailers' shelves. Unlike traditional distribution, which moves goods from manufacturers to consumers, reverse distribution follows the opposite path. These products are sent back through the supply chain for proper disposal, recycling, or refurbishment.

Key aspects include:

- Collection of Defective Items: This includes everything from damaged merchandise to expired goods.

- Return Through Supply Chain: The products are sent back to the manufacturer or a designated processing facility.

- Final Disposal or Repurposing: Depending on the condition, items may be recycled, repaired, or disposed of appropriately.

Essentially, reverse distribution ensures that outdated or defective products are efficiently removed and handled, maintaining the integrity of the retail environment.

How Can Ecommerce Organizations Handle Reverse Logistics to Ensure It’s a Low-Cost Transaction?

To keep reverse logistics affordable, e-commerce organizations need a strategic approach. A great starting point is to combine returns with deliveries wherever feasible. This consolidation minimizes transportation costs by making the most of existing delivery routes.

Another effective tactic involves partnering with third-party logistics providers. These experts can offer specialized services that streamline the returns process, often at a lower cost than handling it in-house.

Moreover, it’s crucial for ecommerce businesses to dig deep into the causes of frequent returns. Identifying the root issues—whether they stem from product quality, unclear descriptions, or shipping errors—allows companies to devise targeted strategies to minimize these problems.

In essence, by integrating deliveries and returns, leveraging third-party expertise, and addressing underlying issues, ecommerce organizations can make reverse logistics both efficient and cost-effective.

What Is Reverse Logistics Going to Look like Moving Forward?

With the rapid build-up of external pressures in the distribution market, it is well worth considering what is reverse logistics destined to look like in the future.

Reverse logistics will likely play a key role in the viability of business structures, and the quality of reverse logistics processes will foreseeably impact the competitiveness and sustainability of both supply chains and industries as a whole.

Of all the methods of improvement, automation is likely to drive some of the highest rates of innovation within reverse logistics, thanks to its far-reaching and revolutionary benefits.

If you require industrial electrical controls for automation purposes, browse our online shop or request a catalog. Feel free to contact us with any questions.

Disclaimer:

The content provided is intended solely for general information purposes and is provided with the understanding that the authors and publishers are not herein engaged in rendering engineering or other professional advice or services. The practice of engineering is driven by site-specific circumstances unique to each project. Consequently, any use of this information should be done only in consultation with a qualified and licensed professional who can take into account all relevant factors and desired outcomes. The information was posted with reasonable care and attention. However, it is possible that some information is incomplete, incorrect, or inapplicable to particular circumstances or conditions. We do not accept liability for direct or indirect losses resulting from using, relying or acting upon information in this blog post.

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009