Overload Relays

Overload Relays

Reliable & Accurate Protection for Your Motors

Product Resources

Product Features

Configure Your Item Here

Please configure the product to display product details.

What is Overload Protection

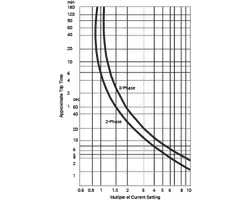

Providing remarkable performance and motor protection through a wide range of features and functions

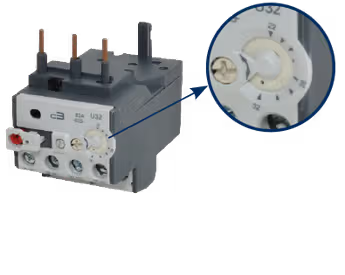

Adjustable Current Setting

Adjustable Current Setting

Phase Loss Sensitivity

Selectable Reset Mode

Seamless Compatibility

Trip Test Function

Visible Markings

Terminal Screws

A wide range of features, functionality, and performance for the most demanding applications

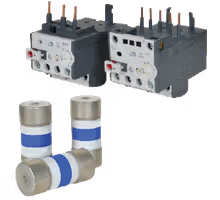

Bimetallic

Mounting Adapters

Reset Push Buttons

Enhance the features and performance of your equipment with c3controls' Bimetallic Overload Relays!

Proven

High Fault Short Circuit Current Rating

Reliability

Added Safety

Ask Our Experts – Customer Support and Engineers At Your Service!

White Papers

Media

Explore Our Family of Products

ISO 9001:2015

Certified

17+ Million Product

Configurations

Lifetime

Warranty

Guaranteed

Same-Day Shipping

Advantage Pricing

Save Up To 40%

c3controls Headquarters, USA

664 State Avenue

Beaver, PA 15009